- Joined

- Sep 20, 2019

- Messages

- 1,333

I don't know anything about your lathe, but I recommend getting it assembled to ensure it's all there and working before you spend money on motors and tool posts. That's quite a project. Have fun and best of luck!

I don't know anything about your lathe, but I recommend getting it assembled to ensure it's all there and working before you spend money on motors and tool posts. That's quite a project. Have fun and best of luck!

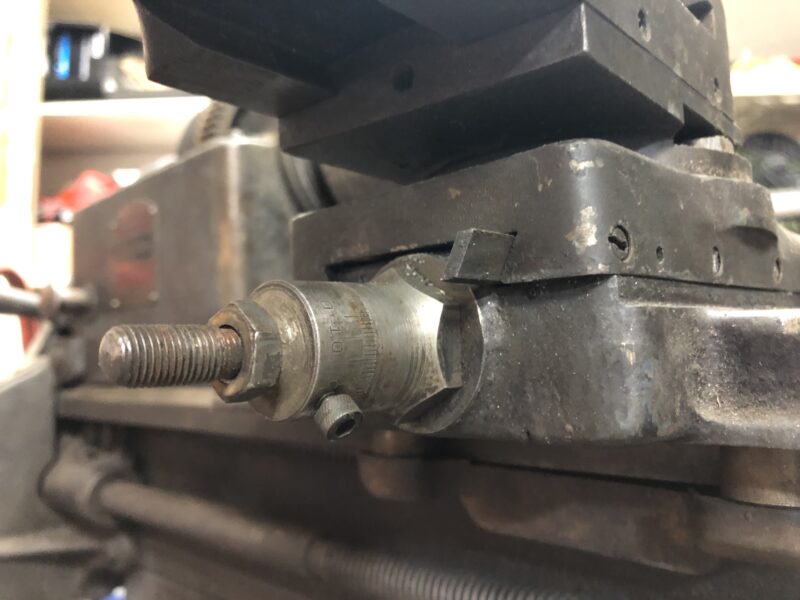

The longer cross slide with the slot in it is for use with a taper attachment. It replaces both the standard cross slide and the chip guard. The compound assemblies should be interchangeable between the two types of cross slidesI'm wondering if anyone recognizes what this compound base is originally from:

The longer cross slide with the slot in it is for use with a taper attachment. It replaces both the standard cross slide and the chip guard. The compound assemblies should be interchangeable between the two types of cross slides

Thank you for this link! My serial number puts this at 1946.You also need a parts book: they can be ordered from Logan along with the operator's manual or can be downloaded

from this site if you are a silver or better supporting member. You can look up the age of your lathe by looking at the FAQ here:

lathe.com. You'll need the s/n when finding parts.