- Joined

- Jan 26, 2024

- Messages

- 48

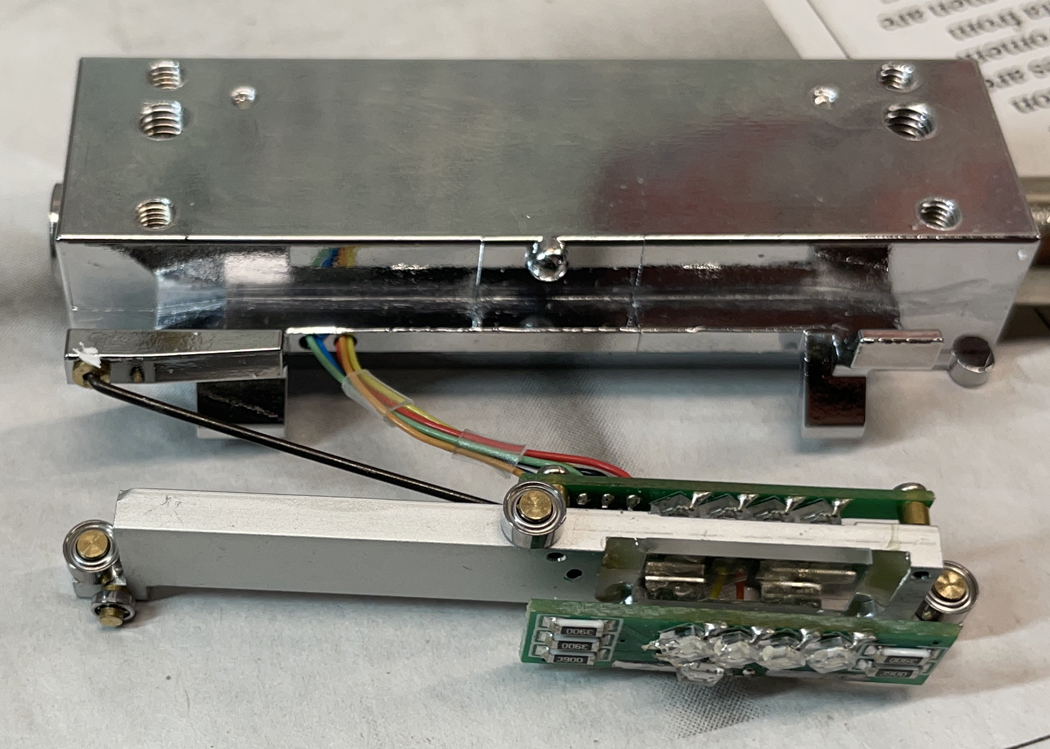

OK, here's what these look like inside:

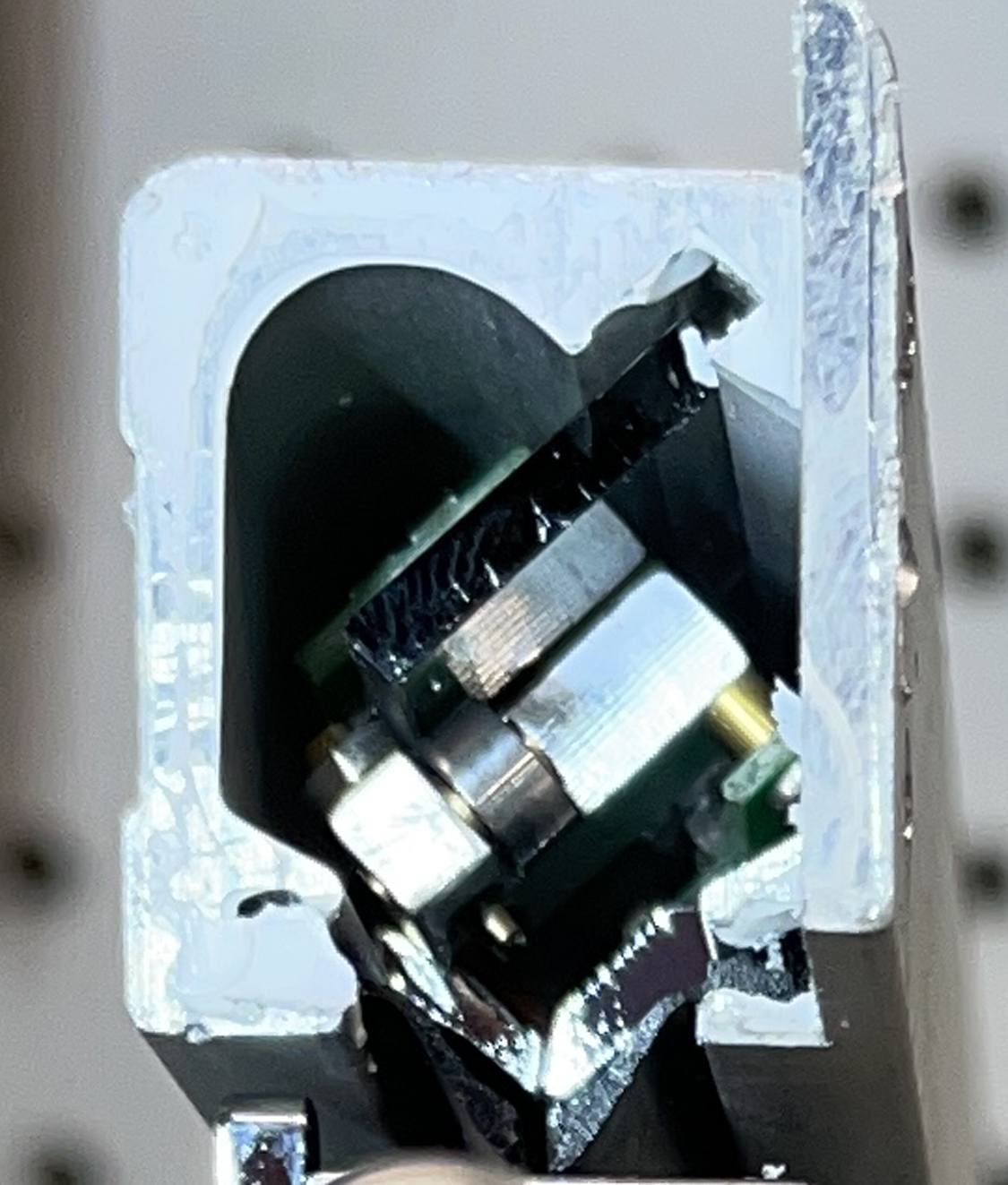

End caps on these are quite different than other glass scales like a ToAuto. This will require some machining and drilling of the extrusion for the end caps to fit:

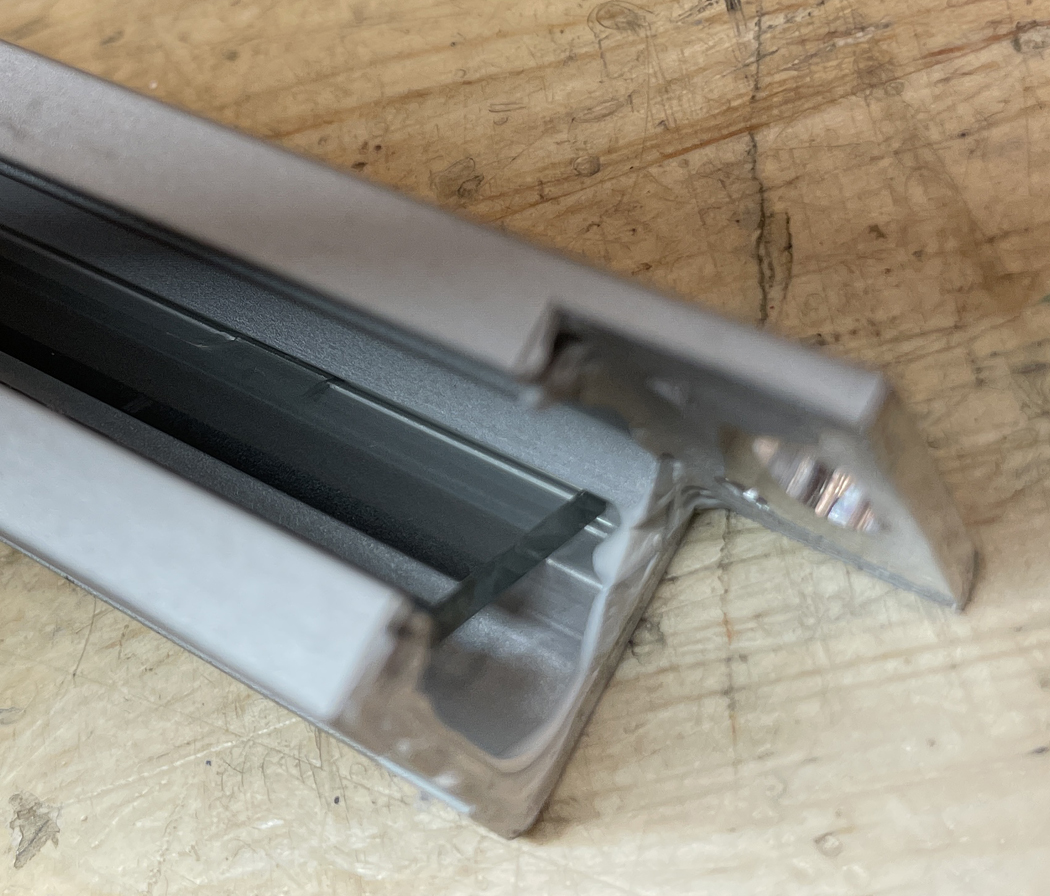

It appears the glass is glued in. I'll try heating up the extrusion to see if it loosens up the adhesive, possibly a hot melt type used here? I think this adhesion is only needed for assembly, looks like the carriage for the read head supports the glass and the end caps/adhesive prevent fore/aft movement of the glass

End caps on these are quite different than other glass scales like a ToAuto. This will require some machining and drilling of the extrusion for the end caps to fit:

It appears the glass is glued in. I'll try heating up the extrusion to see if it loosens up the adhesive, possibly a hot melt type used here? I think this adhesion is only needed for assembly, looks like the carriage for the read head supports the glass and the end caps/adhesive prevent fore/aft movement of the glass