I have quite a lot of thick plate (boiler plate up to 2" thick) and chunky flat stock (eg 6"x2" x 20' etc). I have no way of storing it inside and only cut off chunks with oxy acetylene when I need a piece. Some of this I want to mill, but I know rust is very abrasive. Didn't want to ruin umpteen carbide cutters (say on my face mill), and just wondering if anyone had experience with rusty material as such?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machining rusty stock

- Thread starter Saxguy

- Start date

Pretty much what I've been doing, but just wondered if anyone didn't bother, and what the consequences might be?Knotted wire wheel, or aggressive sanding disc to get through most of it, then a deep enough DOC to get under the surface to clean metal is how I do mine.

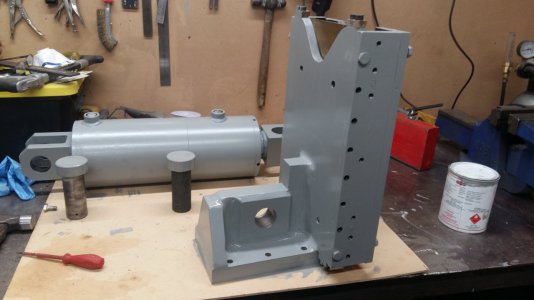

I found that rusty bar on the lathe isnt much of a issue (light rust), as you can just get beneath it with first cut, but wasnt so sure about milling. Not that all my machining is rusty stock mind you... But I'm building a hydraulic press, and using some real beefy material. Just about to make die holder system and multiple die sets. All big stock (by hobby machine standards anyway).

I actually have a large tub of white vinegar that I have used for mill scale. About 10 gallon or so. I might try that for the rust too. Why didn't I think of that?I usually just put it in a Muriatic acid bath. This removes the rust and the mill scale that beats up your cutters. Been doing it for years and it works fine for me.

- Joined

- Apr 22, 2016

- Messages

- 965

I always try to clean the cut area with wire brush, flap disk or grinder before sawing, drilling, milling, just to make the tools last longer. I store most of the stock in an unheated but tightly closed building and before I leave it there I spray and wipe some Blaster on it to help prevent rust.

Aaron

Aaron