- Joined

- Feb 17, 2021

- Messages

- 468

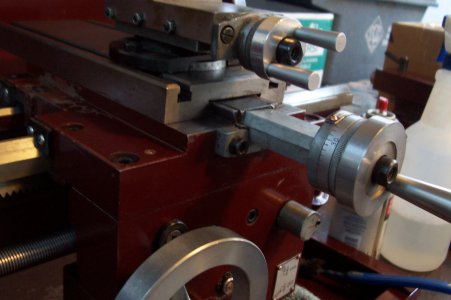

was cleaning around the cross slide and dicovered something the seller didnt tell me about that was hidden

, look closley where the cross slide is attached with that allen head bolt ............maybe some J/B might fix it for now till I can find another part

, look closley where the cross slide is attached with that allen head bolt ............maybe some J/B might fix it for now till I can find another part