-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mentor needed as well as help on a school project!

- Thread starter racer8412

- Start date

- Joined

- Feb 18, 2016

- Messages

- 451

I would think the school still might be your best bet. Does anyone at the school know that you are planning to do this engineering/machining project over the summer? You should check all the resources you can. Be exhaustive and be a pest.

Ask a guidance counselor or a teacher, or both, if there is any way the school might be able to help you obtain a mini lathe on loan over the summer for your project.

It certainly won't hurt to ask around. Sound desperate.

If they can't help you ask if they know of any student help agencies that might be able to help. Act like you won't take no for an answer. After a while they'll all pitch in a buy you a lathe just to get you off their backs.

Ask a guidance counselor or a teacher, or both, if there is any way the school might be able to help you obtain a mini lathe on loan over the summer for your project.

It certainly won't hurt to ask around. Sound desperate.

If they can't help you ask if they know of any student help agencies that might be able to help. Act like you won't take no for an answer. After a while they'll all pitch in a buy you a lathe just to get you off their backs.

- Joined

- Jul 8, 2018

- Messages

- 880

Im prepared for pain and torture! Also an opinion, a lathe is currently a bit past my budget, I could get a drill press, fit a mill base onto it, vice, and rotary table, will that work for the project?

It's not quite that simple. For one thing, you'll have to replace the drill chuck, probably with a collet system. The spindle in the drill press is going to be JTsomething, so you'll need a jacobs-to-R8(or something) adapter.

Then there's the drill press table. This is not that rigid and not that aligned to the drill press. I put an X-Y table on my drill press, and do not regret it - but would not use it as a mill. The table is mounted to a round column, so any load and the table shifts, knocking your X-Y table out of tram.

It is doable? Sure. Is it cheaper than getting a benchtop mill? Probably not. Be sure to price out all of the modifications you need to make, and add those into the cost of the drill press.

I did ask around previously and the issue is that in order to use the machines over the summer an engineering teacher would need to stay and watch me and make sure i dont get hurt or mess up the machines, they said they'd bring it up at their next meeting but it was unlikely they'd find someone.

Interesting project for sure. I'd kind of like to build one. I'll download the info and check it out. I believe I have most of the tooling needed.

Another option for machine access is a local maker space. They might be willing to give you a deal as a student.

Another option for machine access is a local maker space. They might be willing to give you a deal as a student.

- Joined

- Feb 18, 2016

- Messages

- 451

Well, I won't be doing any actual machining on this thing for quite a while anyway. I'm just going through the drawings right now and trying to get a feel for how the whole thing goes together when the parts are built. This might take me a month just to catch up on reading about the Curta Calculator and getting everything together I need to even begin. I do have a real life going on in the background here too.

When I'm ready to start the project I'll post what I'm doing on the Curta Calculator Project thread you started. At that time we'll see if you came up with any machines or tools. I'll do my best to try to suggest ways that you might make the same parts using the limited machines and tools you have.

That's the best I can do for you. I can't buy you a lathe. I don't have that kinda dough either.

When I'm ready to start the project I'll post what I'm doing on the Curta Calculator Project thread you started. At that time we'll see if you came up with any machines or tools. I'll do my best to try to suggest ways that you might make the same parts using the limited machines and tools you have.

That's the best I can do for you. I can't buy you a lathe. I don't have that kinda dough either.

- Joined

- Feb 18, 2016

- Messages

- 451

Interesting project for sure. I'd kind of like to build one. I'll download the info and check it out. I believe I have most of the tooling needed.

That will be great to have more people join in.

Did you get the link for the GitHub page?

ReCurta GitHub

And this too:

Curta Wiki

In fact, I'll go post these on the project thread too.

- Joined

- Feb 18, 2016

- Messages

- 451

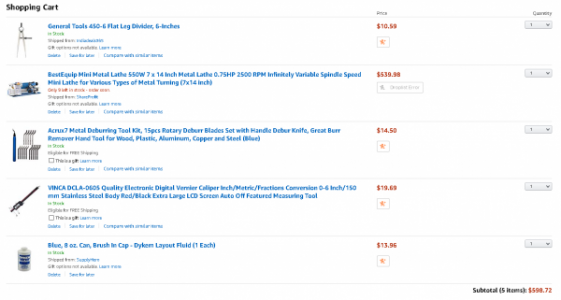

Anytime Tools 5 Piece 3/8" MINI LATHE INDEXABLE CARBIDE INSERT TOOL BIT SET

You could take the blue layout dye and de-burring tools off your list and that would almost pay for these carbide tool bit set.

I use the cheapest blue markers I can find at Walmart for layout dye.

And you can probably find something laying around to deburr with. In fact a small set of hobby files would probably come in more handy.

You might think about going around to yard sales too. You can probably pick up things like files pretty chaep at yard sales.

The carbide tool bits are a far better place to put your money. I don't think that lathe comes with any tool bits. It might come with some High Speed Steel tools which are good to have too. But then you'll need a grinder to sharpen the hight speed steel tooling. Don't worry about buying a grinder. Again, that's another item you might be able to pick up at a yard sale. You don't need a real good grinder. The cheapest one you can find will probably work.

You'll also want a drill chuck for the tailstock.

MINI METAL LATHE TAIL STOCK DRILL CHUCK TOOL WITH MT2 MORSE TAPER ARBOR MT 2

You'll definitely want the tailstock chuck so you can drill holes through the center of rods, etc.

That's such an important item I'm surprised it didn't come with the lathe. But at least the lathe does come with a center in the tailstock.

That should get you started pretty good.

It wouldn't hurt to have a hacksaw and a vice. Again, yard sale is your best bet for those items. You won't need a large vice. The parts you are making are small. Any clamp-on hobby vice would do. You should be able to find something like that at a yard sale really cheap. When you spend the money get things you aren't likely to find at yard sales. Like the tailstock chuck and carbide tool bits.

Don't spend money on anything you can make do with used or otherwise. Like I say, a simple marker pen will replace the $13 layout dye. It doesn't even need to be a blue one. Any color will do.

If you're going to be pinching pennies, pinch them in the right place.

You could take the blue layout dye and de-burring tools off your list and that would almost pay for these carbide tool bit set.

I use the cheapest blue markers I can find at Walmart for layout dye.

And you can probably find something laying around to deburr with. In fact a small set of hobby files would probably come in more handy.

You might think about going around to yard sales too. You can probably pick up things like files pretty chaep at yard sales.

The carbide tool bits are a far better place to put your money. I don't think that lathe comes with any tool bits. It might come with some High Speed Steel tools which are good to have too. But then you'll need a grinder to sharpen the hight speed steel tooling. Don't worry about buying a grinder. Again, that's another item you might be able to pick up at a yard sale. You don't need a real good grinder. The cheapest one you can find will probably work.

You'll also want a drill chuck for the tailstock.

MINI METAL LATHE TAIL STOCK DRILL CHUCK TOOL WITH MT2 MORSE TAPER ARBOR MT 2

You'll definitely want the tailstock chuck so you can drill holes through the center of rods, etc.

That's such an important item I'm surprised it didn't come with the lathe. But at least the lathe does come with a center in the tailstock.

That should get you started pretty good.

It wouldn't hurt to have a hacksaw and a vice. Again, yard sale is your best bet for those items. You won't need a large vice. The parts you are making are small. Any clamp-on hobby vice would do. You should be able to find something like that at a yard sale really cheap. When you spend the money get things you aren't likely to find at yard sales. Like the tailstock chuck and carbide tool bits.

Don't spend money on anything you can make do with used or otherwise. Like I say, a simple marker pen will replace the $13 layout dye. It doesn't even need to be a blue one. Any color will do.

If you're going to be pinching pennies, pinch them in the right place.

- Joined

- Feb 18, 2016

- Messages

- 451

Here's another item that would come in real handy if you can squeak it into your budget.

3/8" Shank 9 Piece Carbide Tip Bore Bar Set

I'm trying to find the cheapest tooling we can get by with.

And this is how I live my entire life. So I'm used to doing this.

3/8" Shank 9 Piece Carbide Tip Bore Bar Set

I'm trying to find the cheapest tooling we can get by with.

And this is how I live my entire life. So I'm used to doing this.