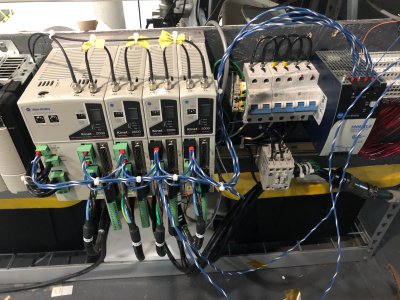

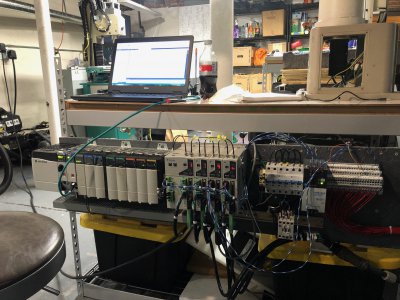

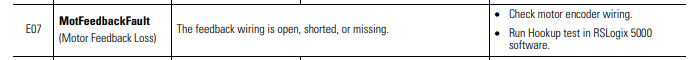

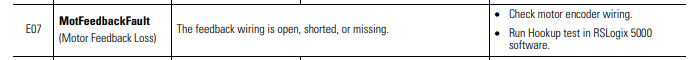

Spent a little more time investigating the E07 error that I get when trying to run the motor. I am guessing the drive doesn't check if it likes the feedback until you try to close the servo loop.

Here is what the manual says about the fault. Not a ton of info, but OK.

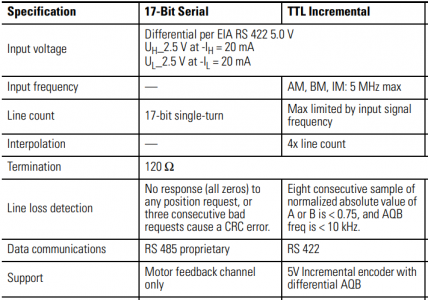

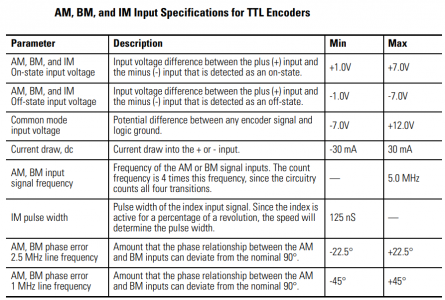

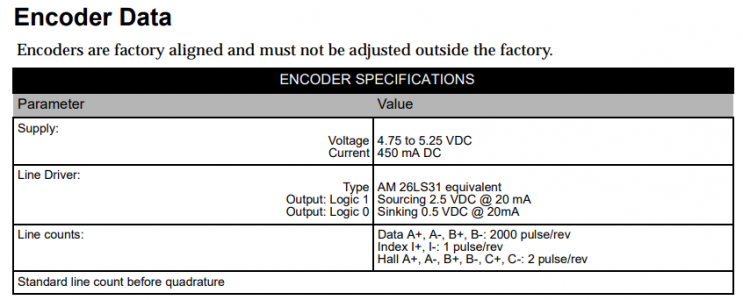

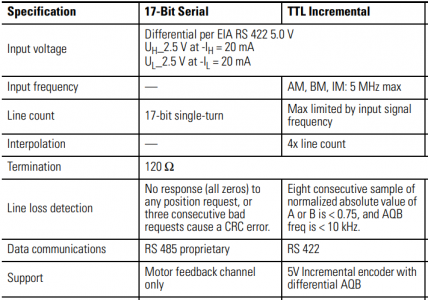

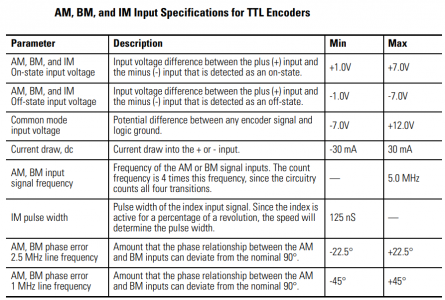

The manual also has a couple more excerpts that state the acceptable signal levels on the feedback. Note that I am using the TTL incremental column.

Specifically the On and Off-State voltages are important. +/- 1V to +/- 7V is acceptable according to this document with -7/+12VDC common mode voltage.

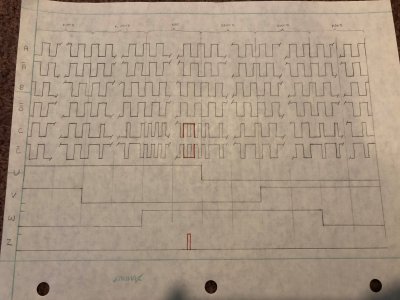

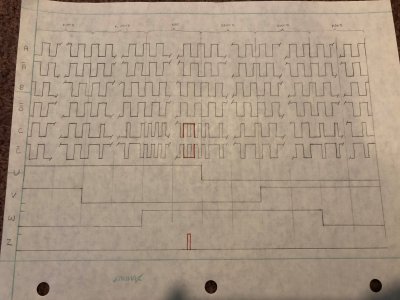

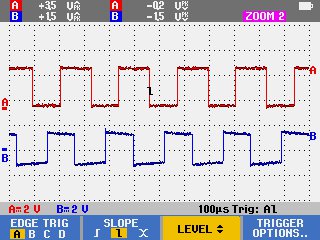

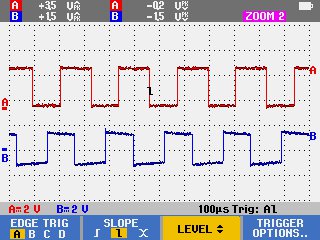

In this scope trace, the positive differential signal is compared to encoder DC COM to identify common mode voltages. It appears the A channel has about -0.2VDC and the B channel has -1.5VDC. These are within the specifications for -7/+12VDC.

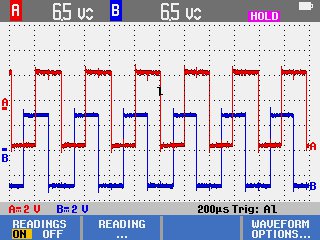

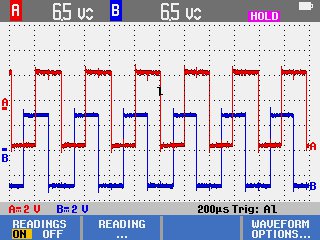

In this second scope trace, the scope is setup to read across the differential signals. The A and B channels show a peak to peak voltage of 6.5VDC which corresponds to a differential amplitude of +/- 3.2VDC which is nicely within the allowable range of +/- 1VDC to +/- 7VDC. Signals are pretty clean too, especially given the number of connectors and unshielded wire segments in the circuit (no motor power applied yet...).

The point of all of this is that the A and B incremental channels look fine. However, the drive is not recording any counts coming into it. I need to play with it some more to try to identify what is going on and why the drive is not reading the signals even though I was able to confirm they fall within the boundaries.

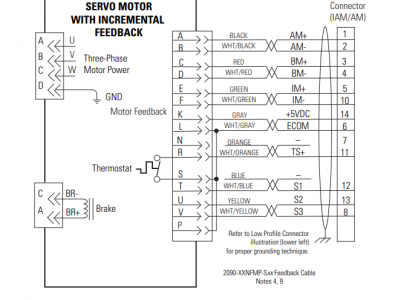

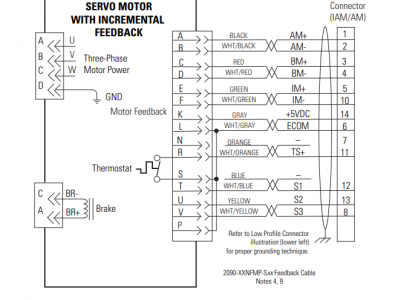

The second issue is the signals that I do not have. These are: Z (index +), Z* (index -), TS (Thermostat), S1 (Hall Commutation Signal 1), S2 (Hall Commutation Signal 2), and S3 (Hall Commutation Signal 3).

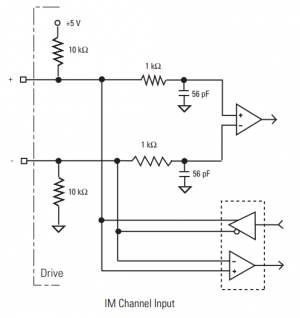

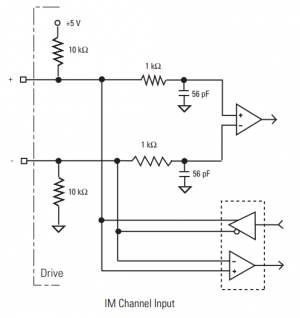

The Z (index) input circuitry according to the manual looks like this. Note the weak pull up and pull down resistors on the input channels. This suggests to me that the input will be biased to 5VDC (differential) if disconnected which is a valid high state. I have also tried tying the + input to 0V and the - to +5V to drive the circuit into a -5VDC (differential) voltage which is a valid low state. Neither of these have prevented the E07.

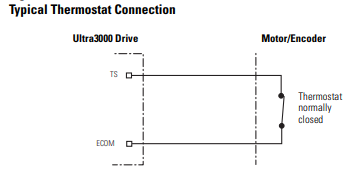

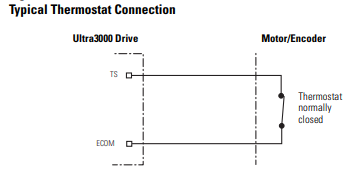

The Thermostat should be disabled from a selection I made in the CMF file, but just in case I tried grounding it out too. The thermostat is shown between pins 11 and 6. I believe it to be normally closed. I tried leaving this open and tried tying it to DC COM. Neither changed the E07. My motors do not have integral thermostats.

If this were the issue, I'd expect to get an E04 - Motor Overtemp Fault.

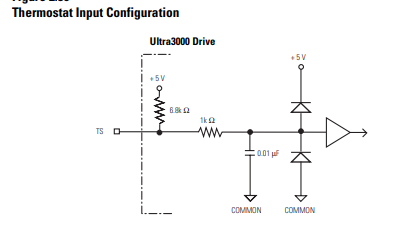

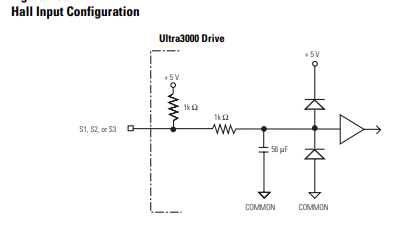

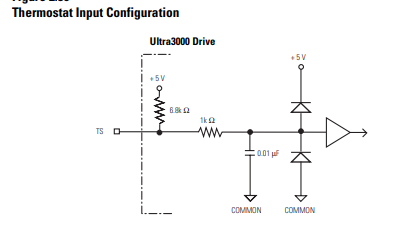

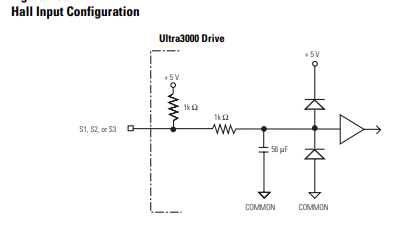

Here are input diagrams from another drive (Ultra 3000), but I'd expect similar or identical circuitry on the Kinetix 2000.

Finally we come to the hall effect inputs. These should be disabled by my selection of Incremental AQB feedback w/o Halls in the CMF file, however this configuration is not used on any Allen Bradley motor. It is supported in the drive firmware from everything I have found, but there is no documentation on how to use this feature. I can't find any input specifications or wiring diagrams either. I tried leaving them floating and tying them to DC COM, but that did not help the E07 either.

Here is an input diagram from another drive (Ultra 3000), but I'd expect similar or identical circuitry on the Kinetix 2000.

If this were the issue, I'd expect to get an E11 - MotFeedbackFault, Illegal Hall State.

As a recap: Whenever I MSO (command to turn servo on) or run the Command & Feedback hookup test (checks drive output and feedback wiring), the drive immediately faults with an E07. In the Quick View pane (notification window in Studio 5000 PLC programming software), the axis lists a Drive Fault of “MotFeedbackFault, FeedbackFault, ManufacturerSpecificFault”.

I tried the following wiring methods to try to trick the drive to accept the signals.

• Wired only A, A*, B, B*, 5V, COM

• Wired A, A*, B, B*, 5V, COM + tied Z* to 5V

• Wired A, A*, B, B*, 5V, COM + tied Z, Thermostat to COM + tied Z* to 5V

• Wired A, A*, B, B*, 5V, COM + tied Z, S1, S2, S3, Thermostat to COM + tied Z* to 5V

So far I cannot enable the motor without a fault.

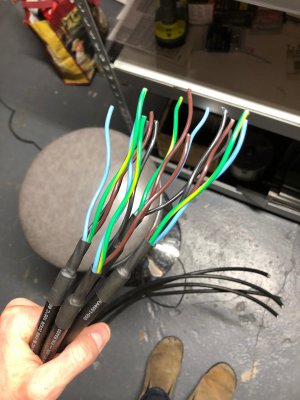

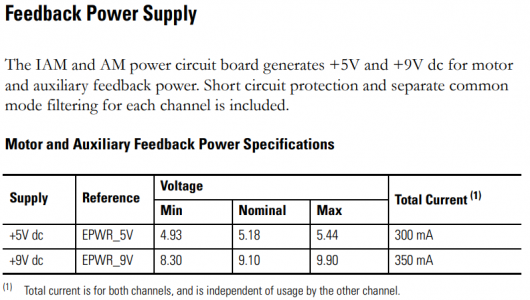

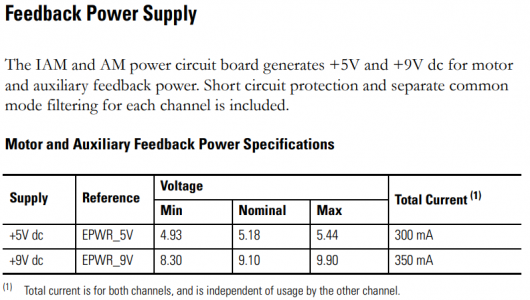

One final thing to note is this table from the manual describing the encoder power supply inside the drive. All 4 encoders have their power connections tied in parallel internal to the robot. I do not think it is wise to try to parallel the power outputs from the different drives, so 1 drive will end up powering all 4 encoders. This might require more power than the supply can deliver and force me to purchase a small 5V external supply.

forum.allaboutcircuits.com

forum.allaboutcircuits.com