-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Models for grinding HSS Lathe Tools

- Thread starter mikey

- Start date

No idea, he'll come back to me in a day.What happens when stuff gets mailed up there?

I suppose that I'll make some tooling by basing on these models, perfectly as possible. Learning from the process, could be made easier with some angle references on the grinder plate. Then pass off these models to someone else in Canada.If you get mail from the US what is the procedure?

- Joined

- Feb 17, 2021

- Messages

- 468

I for one am new to the lathe game and think learning HSS tooling is an art and something Id be good at. like it or not have decided and already have a set of HSS tooling I will study and copy as a guide being Im more of a "hands on guyIn a recent thread by @Darkbluesky, http://www.hobby-machinist.com/thre...tools-ideas-of-what-to-buy.62043/#post-511618, @ttabbal joked about sending me blanks to be ground into lathe tools ... he was joking! But it got me to thinking ... yeah, I know it's not a good thing when Mikey gets to thinking ... but it got me thinking that reading about how a tool is ground and having a decent tool in your hands that you can see and touch are two different things.

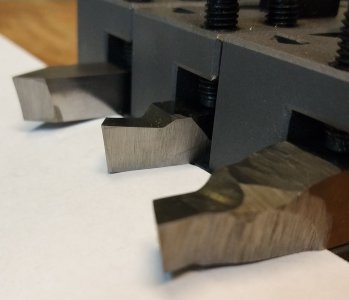

So, what if I ground a set of tools from 3/8" mild steel keystock (just to discourage some bozo from actually trying to cut something with the models) so people could hold it in their hands to look at. You could use them to plop onto your tool rest to see what the rest angles should be and maybe how your hands have to align to grind the tool. You could also buy some keystock and duplicate them for a permanent reference, and then pass them on to the next guy who wants to have a look.

I'm thinking of making THREE sets of these model tools and mailing them out to guys who are interested. We would need to figure out a list if there are more than three guys interested in seeing them, and YOU GUYS need to sort out how to keep track of these things. I would guess one to two weeks of holding time per person would be reasonable and the guy who has them would pay to flat rate ship it to the next guy on the list. Naturally, the only guys who can get on the list would be members of the HM forum.

As to which tools to include in the set, I'll leave that to you guys. We can discuss it here and see if we can come to some consensus. I will probably write a set of notes with details on how each tool is ground and why the angles are what they are and how you can modify them to better suit your needs; these notes would be posted to this thread.

I don't know if this is of interest to anyone but on the off chance that it is, let's talk about this and see if we can make it real. I'll spring for the keystock, grind the models and send them out. After that, you guys need to sort out how to get them distributed. The last guy on the list can hang onto them until some other HM member contacts them or you can send it back to me so I can do the same.

Let me be very clear about one more thing. The models will be of tools as I grind them for use in my shop on my lathe(s). It is one way, not necessarily the right way or the only way. My hope is that it will help you to find your own way of grinding tools that work for you.

Thoughts?

Mikey

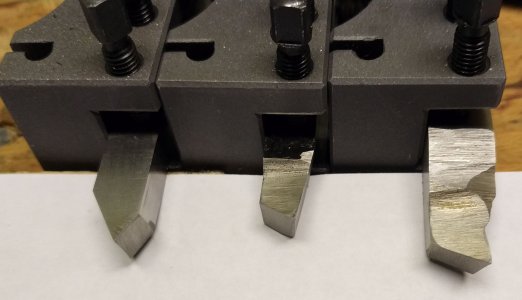

Update after getting these model tools from @Z2V and I have been able grind all them from HSS blanks ( except one that's ugly to me ).

The Square tool looks well done to me, the Knife tool is ugly because I have used one of my former brass/copper HSS tool and it looks more some of excrement looking than normal.

As for my threading tool, I also made it but I don't have the fishtail ruler to check the cutter shape. I could 3D print one quick for this.

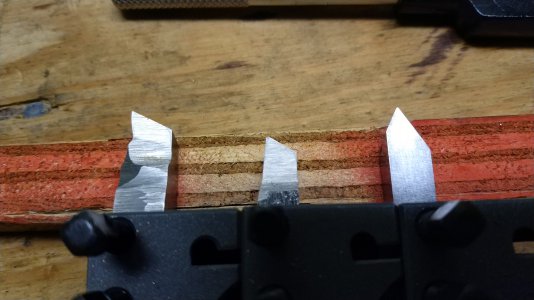

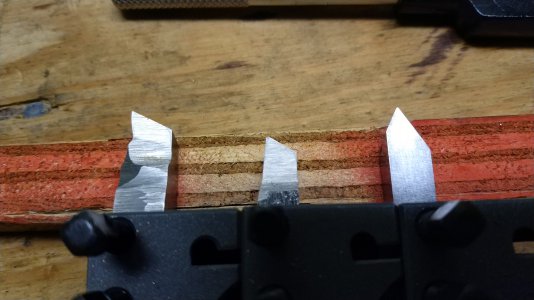

My test cuts with 6061 at the top and 12L14 at the bottom.

The knife tool could be crap because I did grind from brass/copper hss bit to this.

The Square tool looks well done to me, the Knife tool is ugly because I have used one of my former brass/copper HSS tool and it looks more some of excrement looking than normal.

As for my threading tool, I also made it but I don't have the fishtail ruler to check the cutter shape. I could 3D print one quick for this.

My test cuts with 6061 at the top and 12L14 at the bottom.

The knife tool could be crap because I did grind from brass/copper hss bit to this.

Attachments

- Joined

- Dec 20, 2012

- Messages

- 9,422

Good job, Fermic! You did way better than I did when I started out. You did a nice job on the square tool. The knife tool needs work but I would focus on learning to grind and use the square tool; it will give you the most mileage for now.

Your cuts look good and will get better as you learn to use these tools. Just from the pics, it looks to me like you need more speed for the aluminum.

Your cuts look good and will get better as you learn to use these tools. Just from the pics, it looks to me like you need more speed for the aluminum.

Good job, Fermic! You did way better than I did when I started out. You did a nice job on the square tool. The knife tool needs work but I would focus on learning to grind and use the square tool; it will give you the most mileage for now.

Your cuts look good and will get better as you learn to use these tools. Just from the pics, it looks to me like you need more speed for the aluminum.

Thanks to you with these models, I can grind my HSS blanks into these nice working HSS tool bits.

The knife tool, I am figuring how to use it as intended with my QCTP. I kinda got some spirals on the face of 12L14 when I faced it, I bet this tool isn't for roughing work.

For 6061 aluminium / aluminum, I spun the piece at 1000 rpm and cut it manually the fastest I could with the handwheel.

For 2000 rpm, I don't know if my worn tooth gear on the motor of my lathe will cause any problems for me, will revisit later.

- Joined

- Dec 20, 2012

- Messages

- 9,422

Remember that the knife tool is intended to be a facing tool. It has other uses but it excels at facing. It will leave a near mirror finish in almost all materials. It will also work well when taking micro-cuts in thin material because it does not deflect much at all. It does not work well for normal turning; it does not have an end cutting edge to contact the work so it cuts with the nose radius and that leaves fine lines in the finish - not ideal. For most turning, use the square tool. If you need to take a very tiny facing cut with control, pull out the knife tool.

I often turn aluminum at the max speed my lathe can run at, at least for pieces 3/4" OD or less. You will be surprised how well a good square tool cuts aluminum at high speeds.

You will find that the typical calculations for rpm are just rough guidelines, especially when using HSS tools ground like yours. Your tools will cut more efficiently and can work at higher speeds. Accordingly, you can feed faster as well. Mess with this and learn how your tools like to cut. This his how we learn what our lathes want with the tools we use.

I often turn aluminum at the max speed my lathe can run at, at least for pieces 3/4" OD or less. You will be surprised how well a good square tool cuts aluminum at high speeds.

You will find that the typical calculations for rpm are just rough guidelines, especially when using HSS tools ground like yours. Your tools will cut more efficiently and can work at higher speeds. Accordingly, you can feed faster as well. Mess with this and learn how your tools like to cut. This his how we learn what our lathes want with the tools we use.