-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Models for grinding HSS Lathe Tools

- Thread starter mikey

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

You might want to try putting the stone in your non-dominant hand and hold the tool in your dominant hand. Get the face of the tool flat on the stone and feel it register, then push or pull and make a single pass and then repeat. It might work better than laying the stone on the bench. I hone my tools as above.Hone is on a flat machined 3/8" thick aluminum plate. It isn't fixed to the bench, but just sits on it. I just move the tool in one direction, pick it up and return to start. I think I'm basically doing what you have written.

I think I'm not grinding enough with a fine grit on the belt sander. That's forcing me to get a workout honing to get rid of the grooves. I'll try a finer belt for the finishing before moving on to honing. That might be the root issue.

- Joined

- Dec 18, 2019

- Messages

- 6,538

That's really a good idea. I find my fingers go numb grasping the steel non-sharpened edges. I will try this. I'll see if I can get finer belts as well. Think I'm spending far too much time on hand honing, since I'm not grinding with fine belts. Definitely worth a try!I’ll put the tool in side a piece of 3/8” automotive hose to make it easier on the old hands. I’ll usually grind with the finest ceramic belt then hit it with a 300 grit AO belt.

View attachment 405105

- Joined

- Dec 18, 2019

- Messages

- 6,538

I will give this a try. What approximate stone size are you using? My bench stones are 75 x 170 mm, but I do have some smaller ones which might be easier to hold. I think I have 3 stones about playing card size that might work.You might want to try putting the stone in your non-dominant hand and hold the tool in your dominant hand. Get the face of the tool flat on the stone and feel it register, then push or pull and make a single pass and then repeat. It might work better than laying the stone on the bench. I hone my tools as above.

Looks like I should get some finer belts as well. Been wasting a lot of time just removing grinding marks rather than minor honing the surface.

- Joined

- May 13, 2019

- Messages

- 1,016

I was having the same trouble you guys are having with honing. The belt grinder was pretty straightforward in getting the geometry right, but the honing was giving me issues.

I now use the belt grinder for honing. I use 600 and 1200 grit belts and the surface is like a mirror and much easier than using the diamond honing cards.

I now use the belt grinder for honing. I use 600 and 1200 grit belts and the surface is like a mirror and much easier than using the diamond honing cards.

I was having the same trouble you guys are having with honing. The belt grinder was pretty straightforward in getting the geometry right, but the honing was giving me issues.

I now use the belt grinder for honing. I use 600 and 1200 grit belts and the surface is like a mirror and much easier than using the diamond honing cards.

As long as you can accurately align the faces with the belt, it's a good method. But even a slight misalignment will grind all sorts of interesting facets on the tools. Nothing wrong with the method, it can just go sideways fast. Just mentioning it in case new guys have an issue so they have an idea of what to look at.

- Joined

- May 13, 2019

- Messages

- 1,016

As long as you can accurately align the faces with the belt, it's a good method. But even a slight misalignment will grind all sorts of interesting facets on the tools. Nothing wrong with the method, it can just go sideways fast. Just mentioning it in case new guys have an issue so they have an idea of what to look at.

You are correct. After swapping belts, you must make sure the angles are the same as before. I use a digital level that's accurate to 0.1 degree to reset my table after changing belts. This seems to be good enough and works for me.

- Joined

- Dec 20, 2012

- Messages

- 9,422

I mostly use the credit card size for honing. In my hands, it takes only a few strokes per face. Just keep in mind that I've honed thousands of tool bits so this might not be the average experience.I will give this a try. What approximate stone size are you using? My bench stones are 75 x 170 mm, but I do have some smaller ones which might be easier to hold. I think I have 3 stones about playing card size that might work.

Looks like I should get some finer belts as well. Been wasting a lot of time just removing grinding marks rather than minor honing the surface.

Honing is a skill and like any skill, it takes time to acquire. It's like learning to file accurately ... not that easy to do at first but it comes with time.

- Joined

- Dec 18, 2019

- Messages

- 6,538

Couldn't find my CC sized hones, but found some Eze-Lap's. This honing skill seems to be eluding me.I mostly use the credit card size for honing. In my hands, it takes only a few strokes per face. Just keep in mind that I've honed thousands of tool bits so this might not be the average experience.

Honing is a skill and like any skill, it takes time to acquire. It's like learning to file accurately ... not that easy to do at first but it comes with time.

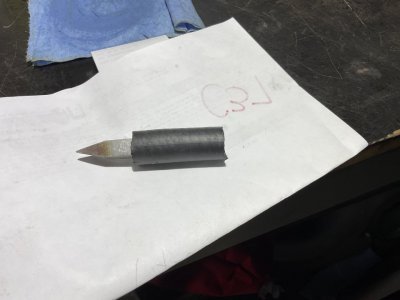

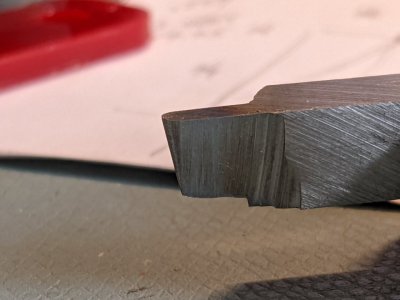

Ground an o-ring tool on my belt sander with 60 grit and 120 grit ceramic belts. That's as fine as I have. Then used my carbide grinder with a CBN wheel to do the rounding and finish to size. The CBN wheel gives a relatively fine finish. Honing went pretty slow but ok. Things go south when I have to change hands. I stroke from the "I don't care side" to the "I care about this edge" side. I still manage to slightly ruin the cutting edge. I can maintain one hand in position, but not two at the same time, it appears. I need some kind of fixture to help, as this feels like madness, doing it over and over again and expecting a different (good) result.

Hope I saved this tool bit enough to do what I want to do, which is to cut a simple rounded o-ring groove. Total DOC of the groove will be 0.050, which is the radius of the tool.

Me honing the tool seems to make the piece worse rather than making it better. Fortunately this is for 6061 aluminum. I'll try a test cut and see how it does.