- Joined

- Dec 18, 2019

- Messages

- 6,464

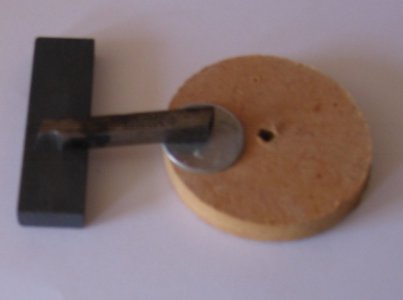

I can grind them ok. Where I fall apart is in honing them. I end up ruining the edges more often than not. I need to make a couple of honing guides. Just can't hold the small faces consistently flat to the honing surfaces. The largest face is easy, it's the smaller ones that I have trouble with. Keep on rocking them and wrecking the edge. Kind of like Sisyphus, almost there and the rock goes tumbling back down the hillfor those of you that can't grind HSS worth a damn.

I recommend these 4 videos from Mr. Pete. They will help you grind if you insist you can't

I will watch these videos. Hope to find something that works.

What do you do for small HSS tools, the kind you need to inspect or grind under a microscope? I need to make a grooving tool with a 0.05" radius. Hogging out the material is not that hard, but how to do the fine work in a reasonable amount of time? Seems like one needs a fixture, but I'm having trouble even imagining one. Can you point me in the right direction?