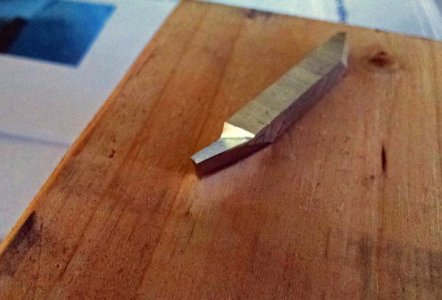

Ok, after months of anticipation I've turned my first bits.

I started off with Mikey's square tool. I messed up my first attempt by grinding the top angle in the wrong direction, but luckily I bought the special beginners blanks that come with two ends, and think I got it right on my second attempt.

The top angle was my biggest challenge, it is an awkward angle on the grinder. First attempt I got mixed up and ground from the left putting the slope in the wrong direction.

Mikey your instructions worked great. I printed them out and just followed along step by step.

I just used a small piece of scrap 2x4 to push the bit against the wheel. That worked, but I think I'll cut it down into a 2x2 or 1x2 for the future. I was really surprised at how fast the grinder removed the metal. I think it only took me about 10 minutes to complete both the mistake and its replacement.

I'll need additional practice to get comfortable, but I think my first (ahem, second) attempt created a functional tool so I'm pretty happy. I fully expected to trash 4 or 5 blanks figuring stuff out. Helps to have good instructions.