- Joined

- Jun 12, 2018

- Messages

- 712

I want to run this project first with you guys, the experts, before I decide to do anything.

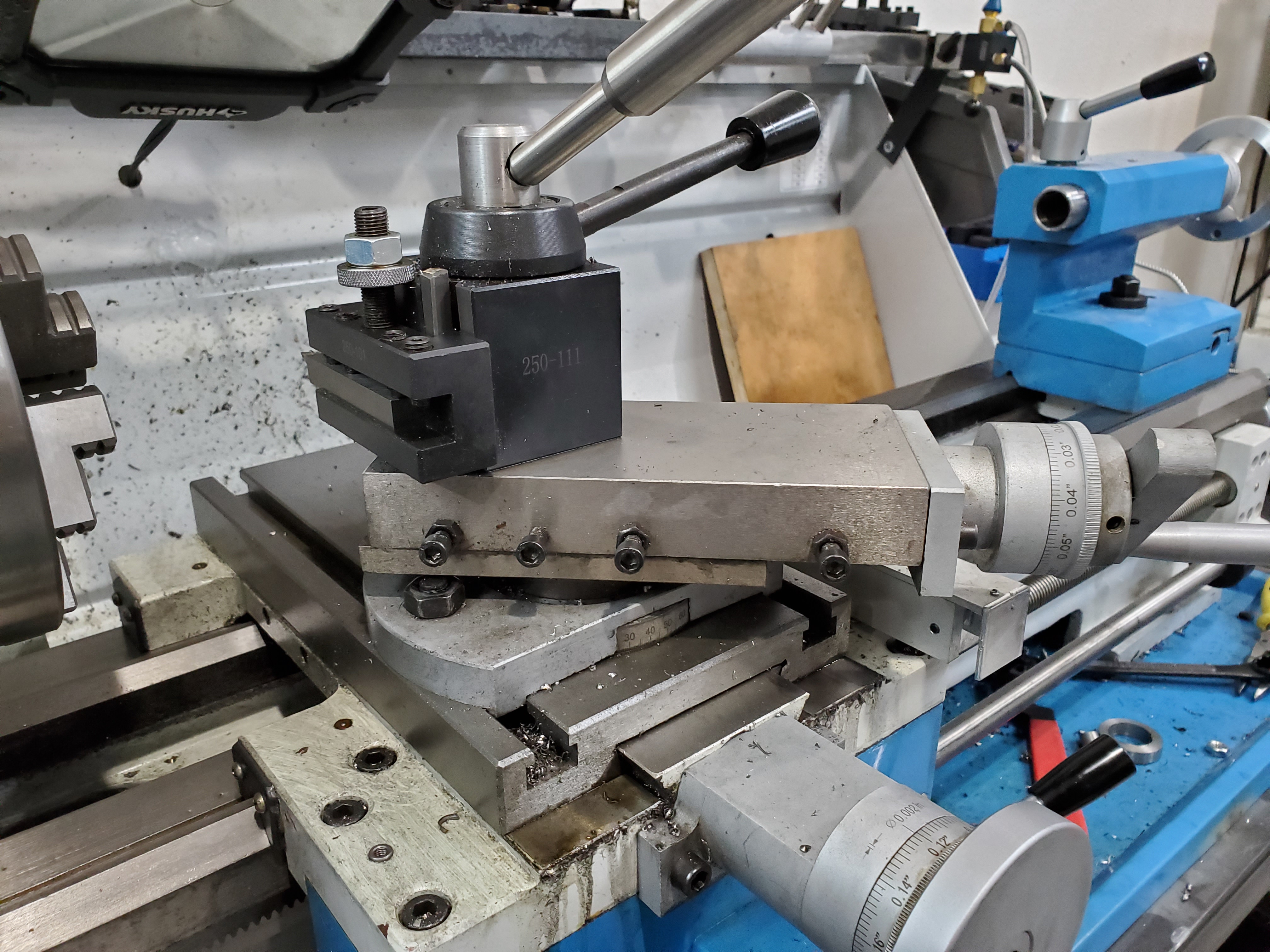

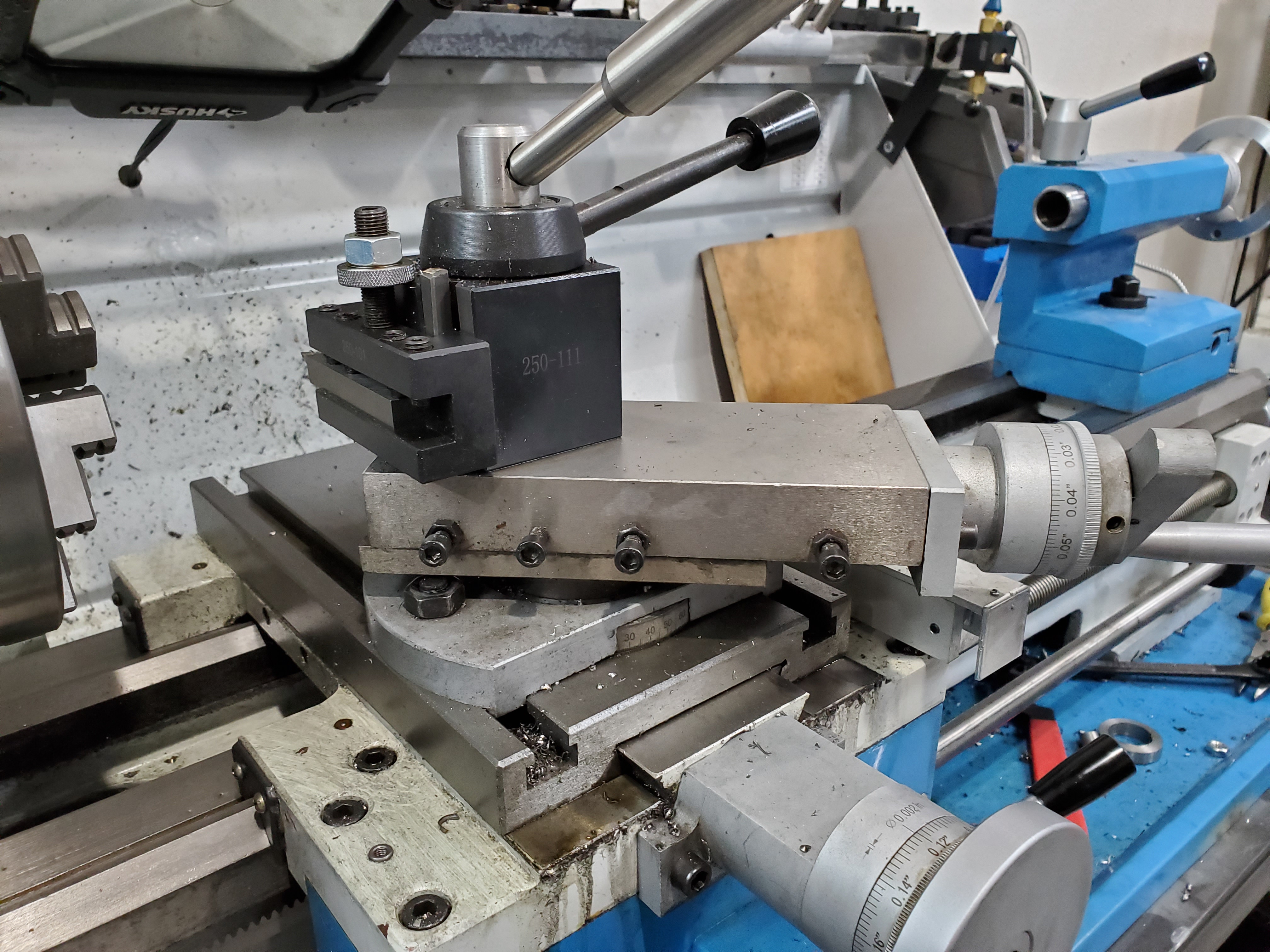

I have a Precision Matthews PM1127 lathe. With the DRO that came pre-installed, I can't line up the cutting tool on the QCTP on the right side of the work piece if I'm holding it with a dead center. Even with the quill of the tailstock extended all the way, I'm about an inch short of the cutting tool being able to cut from the right side of the work piece. The set screw protecting the DRO scale is hitting the tailstock. I can't move the glass scale of the X axis DRO any closer.

The shaft of the QCTP is on the left side of the compound slide. I was thinking of making another shaft that will go closer to the center of the compound slide and mount the QCTP on there. I tried turning the compound to where the dial is on the left side, but it just gets in the way.

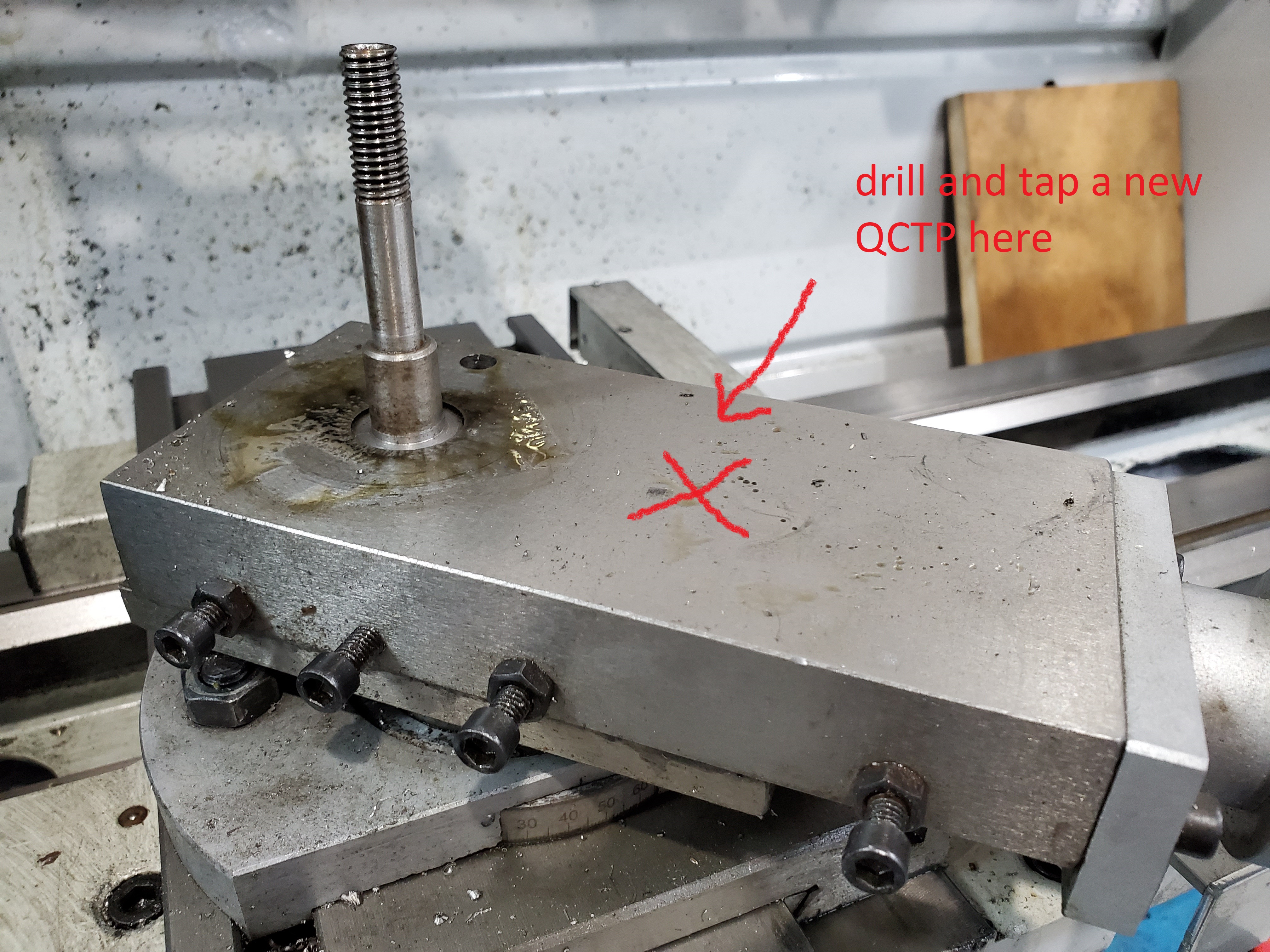

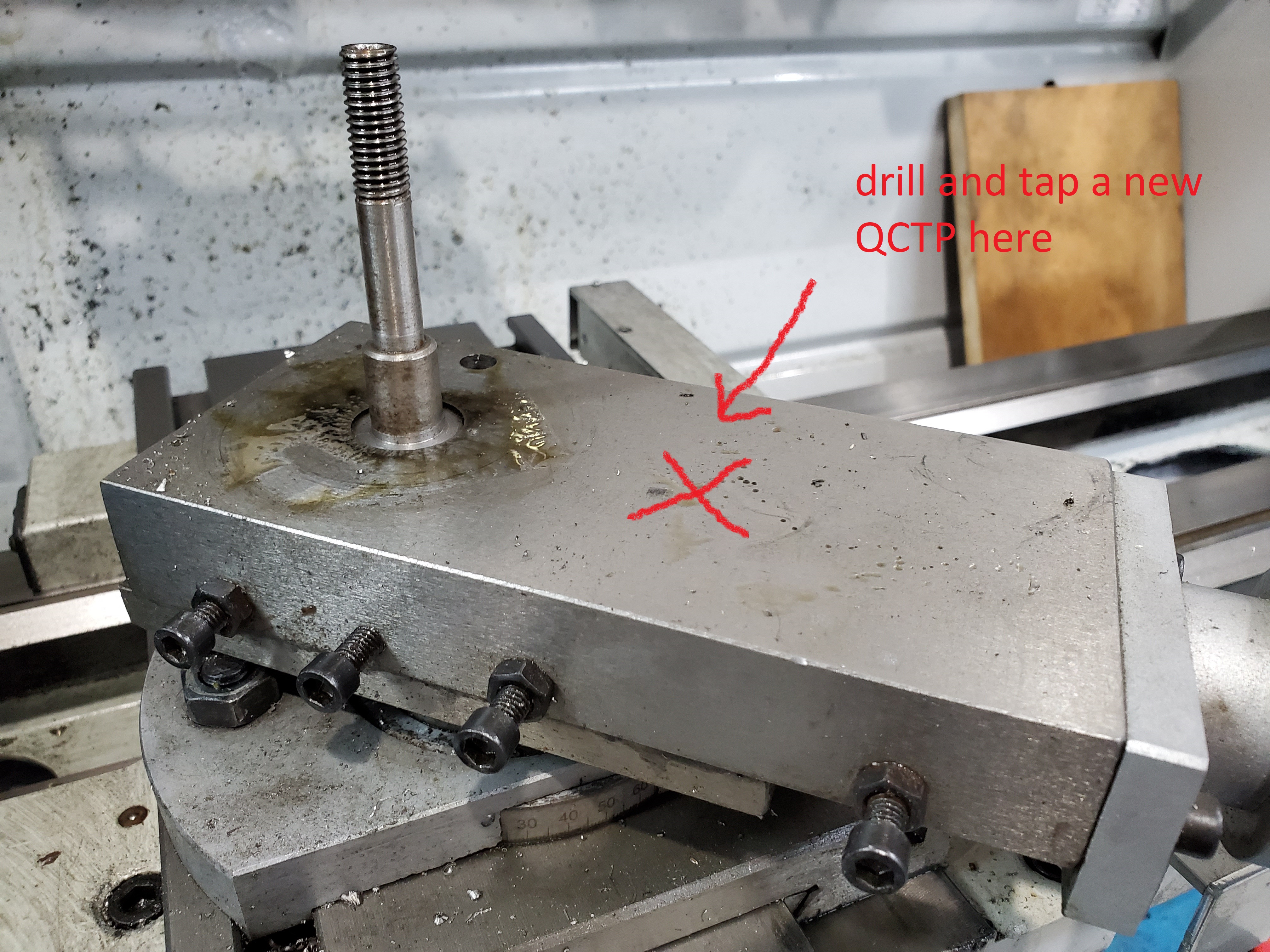

My plan is to drill and tap another shaft to where my cutting tool can finally turn a workpiece from all the way to the face of the work piece to the head stock when the work piece is supported by a dead or live center.. and also I don't have to stick out my tailstock quill all the way out and lose ridgidity.

Another issue is the stock QCTP shaft has a very loose tolerance. It's way off the diamater of the diamater of the QCTP and I don't like that for some reason, the shaft tapers to a much smaller size.. I don't understand why it's designed this way.

I have a Precision Matthews PM1127 lathe. With the DRO that came pre-installed, I can't line up the cutting tool on the QCTP on the right side of the work piece if I'm holding it with a dead center. Even with the quill of the tailstock extended all the way, I'm about an inch short of the cutting tool being able to cut from the right side of the work piece. The set screw protecting the DRO scale is hitting the tailstock. I can't move the glass scale of the X axis DRO any closer.

The shaft of the QCTP is on the left side of the compound slide. I was thinking of making another shaft that will go closer to the center of the compound slide and mount the QCTP on there. I tried turning the compound to where the dial is on the left side, but it just gets in the way.

My plan is to drill and tap another shaft to where my cutting tool can finally turn a workpiece from all the way to the face of the work piece to the head stock when the work piece is supported by a dead or live center.. and also I don't have to stick out my tailstock quill all the way out and lose ridgidity.

Another issue is the stock QCTP shaft has a very loose tolerance. It's way off the diamater of the diamater of the QCTP and I don't like that for some reason, the shaft tapers to a much smaller size.. I don't understand why it's designed this way.

Last edited: