- Joined

- Aug 16, 2015

- Messages

- 32

I use the smithy box/stand and so far it seems to have all the room I need. I just keep the vises and stock on the shelves instead if in the drawers. That hf box looks nice though.I haven't even started buying tools/accessories yet... using the information here to make a list. Is the Harbor Freight tool chest above large enough to store everything you need for a mill?

Sent from my SM-N910V using Tapatalk

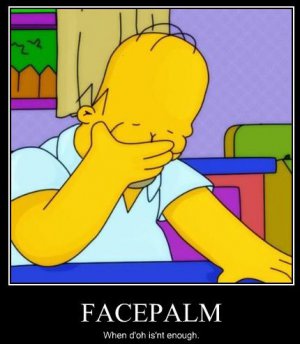

Sorry, just had to say that!

Sorry, just had to say that!