- Joined

- Jun 22, 2023

- Messages

- 328

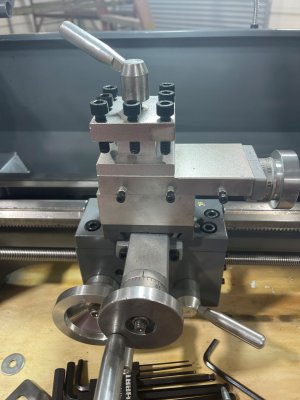

well i bit the bullet and bought a MX-600A (1100w brushless 8.7X23.6 with a F/R H/M/L gearbox and a 1.5" spindle bore, shipps with a steady rest, a follow rest and a dead center) off of e-bay, after getting it and turning some steel (does a decent job IMO). I got this expecting a box of lathe like parts that I would need to cleanup, tune and refitted to have a working lathe, but was pleasantly surprised. now it has issues but I was looking for a project anyway, to start with the gearbox would not shift between forward and reverse, the steady rest is off center (by a lot) but the spindle runout is less than .0005" the total runout at the chuck (1") in front is a little over .005", the bed varies by about .001" over the 24" (measures with test dial from the saddle to the v-way for the tailstock). out of the box the tailstock is dead center of the spindle, the real issue that i fighting with the seller is that the compound slide came as an alum extrusion while the e-bay listing clearly indicates a solid steel riser and dovetail slide.

the seller is trying to keep from RMAing it and has offer to send me a new steady rest and $60 for the compound (not acceptable IMO but still working on it) and the seller informed me that the rpms needed to be in the 700 rpm range not 200 rpm as the safety label indicates, and after shifting it a few times at 700 rpm it smoothed right out and is now acceptable.

I doubt that the seller will be able to source a steel compound for it and may just build me one when it gets to be an issue (the compound slide is threaded into the alum. extrusion and IMO will fail)

the lathe weighs around 180lbs so still portable but not light (for a mini), i have mostly decided to keep it unless the seller pisses me off, i will post updates and the sellers name after i get things worked out with them.

over all i'm liking what i'm seeing, it is not a PM 10x20 or even a grizzly but for 1200 shipped it is a good place to start if you want to play with a small lathe. this is the best combo that i could find to meet my criteria.

the seller is trying to keep from RMAing it and has offer to send me a new steady rest and $60 for the compound (not acceptable IMO but still working on it) and the seller informed me that the rpms needed to be in the 700 rpm range not 200 rpm as the safety label indicates, and after shifting it a few times at 700 rpm it smoothed right out and is now acceptable.

I doubt that the seller will be able to source a steel compound for it and may just build me one when it gets to be an issue (the compound slide is threaded into the alum. extrusion and IMO will fail)

the lathe weighs around 180lbs so still portable but not light (for a mini), i have mostly decided to keep it unless the seller pisses me off, i will post updates and the sellers name after i get things worked out with them.

over all i'm liking what i'm seeing, it is not a PM 10x20 or even a grizzly but for 1200 shipped it is a good place to start if you want to play with a small lathe. this is the best combo that i could find to meet my criteria.

Last edited: