Well another update. This a great point in the project - seeing all the final components coming together again.

Rolled the cabinet to the location where it will be anchored to the floor. Rough leveled the cabinet and rolled the back six feet. Hoisted the lathe onto cabinet, mount the 3 phase motor, installed the VFD enclosure.

Now working on wiring everything back up.

Question: What type of armor flexing tubing is this? I have only seen/used FMC ”Greenfield” style metal tubing. I have only seen this style on this lathe. Is tubing and fittings still available today?

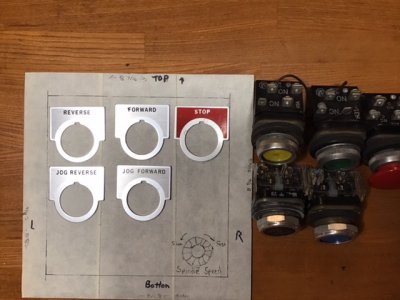

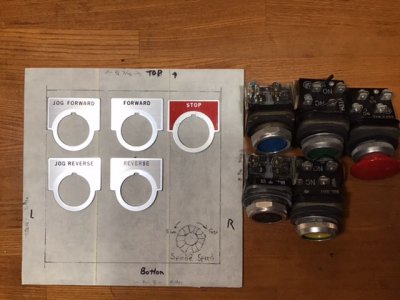

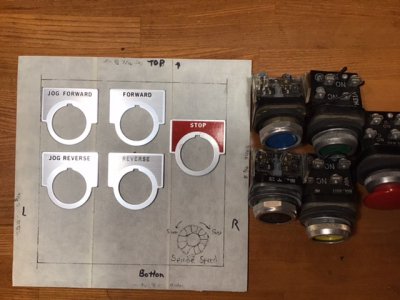

I still have not decide the final layout of the Start/Stop, Forward/Reverse, Jog AB 800T switches.

Does any one have an opinion which prefer switch layouts? The first photo ‘Reverse-Forward-Stop’ was how the switches where original arranged. This is the only lathe I have ever used.

Thanks, Bob G.