- Joined

- Jan 2, 2014

- Messages

- 8,852

Hi everyone,

I have a friend that is very heavy into building electric cars.

Several years ago he converted a regular, gas-powered Toyota Echo to electric.

I helped build a new plate to bolt onto the front of the transmission to mount the single big DC motor.

I also built the motor shaft to transmission input shaft coupler.

He added banks of batteries under the hood, and in the back.

He still has that car running, but now he wants to build something better.

The technology is moving along fast.

He has already bought some motors, and a replacement battery pack from a commercial electric car (I forget which one....).

He has them all on his heavy-duty work bench getting ready for testing.

He wants to connect two of these motors "face-to-face" so that he can load one with the other for testing.

That means he needs a double-ended splined shaft.

He has four Yasa P400RS motors. They are liquid cooled, high-efficiency, high-torque, high-voltage, 3-phase DC motors.

https://www.yasa.com/wp-content/uploads/2018/01/YASA_P400_Product_Sheet.pdf

I had never cut a spline before, but once he found the spec. for what he needed and I had a chance to go thru the Machinery Handbook section and run some numbers I decided to give it a try!

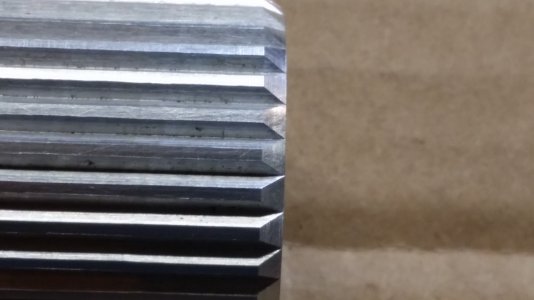

First, I made a test spline from aluminum.

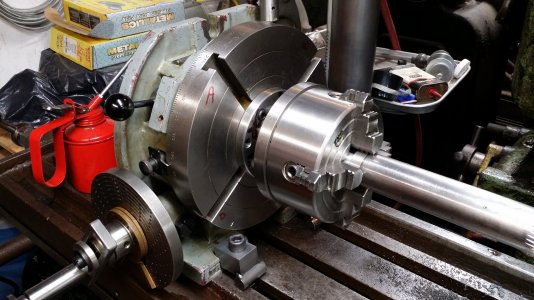

Since I needed to turn down some oversize stock on the lathe before moving to the mill, I thought I could use the same chuck on the lathe as on the rotary table on the mill. I did NOT have long piece of aluminum bar the proper diameter, so I drilled, tapped and connected a smaller bar to the end of the large stock to use as a handle. They were assembled with threaded rod and thread-locker. Since I needed to turn down the ID of the larger piece, it should end up concentric anyway.

Here it is with the smaller bar held in the collet chuck on the lathe and the OD being sized:

When that was done, the work-piece was left in the chuck and the entire thing moved over to the mill:

Unfortunately, I did not (at the time) have a proper height tailstock to match the rotary table.

What I used was a centre I turned on the lathe, held in a 5C-collet, in a spindexer, up on 1-2-3 block stilts:

(you cannot see them, but there's also some parallels laying flat between the 1-2-3 blocks and the spindexer)

Here is cutting a spline (or is it a groove between splines....... )

)

I tried multiple times to upload a video of cutting a spline,

I will try again in a new post...stay tuned.

-brino

I have a friend that is very heavy into building electric cars.

Several years ago he converted a regular, gas-powered Toyota Echo to electric.

I helped build a new plate to bolt onto the front of the transmission to mount the single big DC motor.

I also built the motor shaft to transmission input shaft coupler.

He added banks of batteries under the hood, and in the back.

He still has that car running, but now he wants to build something better.

The technology is moving along fast.

He has already bought some motors, and a replacement battery pack from a commercial electric car (I forget which one....).

He has them all on his heavy-duty work bench getting ready for testing.

He wants to connect two of these motors "face-to-face" so that he can load one with the other for testing.

That means he needs a double-ended splined shaft.

He has four Yasa P400RS motors. They are liquid cooled, high-efficiency, high-torque, high-voltage, 3-phase DC motors.

https://www.yasa.com/wp-content/uploads/2018/01/YASA_P400_Product_Sheet.pdf

I had never cut a spline before, but once he found the spec. for what he needed and I had a chance to go thru the Machinery Handbook section and run some numbers I decided to give it a try!

First, I made a test spline from aluminum.

Since I needed to turn down some oversize stock on the lathe before moving to the mill, I thought I could use the same chuck on the lathe as on the rotary table on the mill. I did NOT have long piece of aluminum bar the proper diameter, so I drilled, tapped and connected a smaller bar to the end of the large stock to use as a handle. They were assembled with threaded rod and thread-locker. Since I needed to turn down the ID of the larger piece, it should end up concentric anyway.

Here it is with the smaller bar held in the collet chuck on the lathe and the OD being sized:

When that was done, the work-piece was left in the chuck and the entire thing moved over to the mill:

Unfortunately, I did not (at the time) have a proper height tailstock to match the rotary table.

What I used was a centre I turned on the lathe, held in a 5C-collet, in a spindexer, up on 1-2-3 block stilts:

(you cannot see them, but there's also some parallels laying flat between the 1-2-3 blocks and the spindexer)

Here is cutting a spline (or is it a groove between splines.......

)

)

I tried multiple times to upload a video of cutting a spline,

I will try again in a new post...stay tuned.

-brino

Last edited: