- Joined

- Nov 27, 2012

- Messages

- 7,854

I recently got a gen2 HF 5 drawer cart to replace my old gen1 cart. Well I decided to keep the gen1 cart. A common mod for the gen1 cart is to replace the gas struts with simple $10 hinges off a Snap-On cart. This allows the lid to open to 90° & my gen1 cart struts were going bad. One of the changes they made to the gen2 cart is that the lid opens to 90°. Aside from better access to the top compartment this takes unnecessary load off the struts when the lid is open on the gen2. Another great thing about the simple hinges is that they won't wear out like my original struts did.

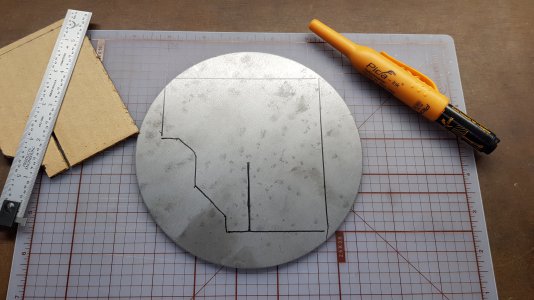

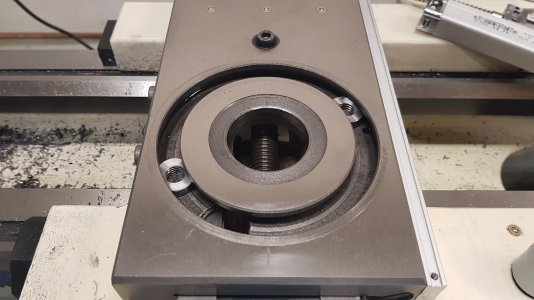

The mounting hole size is smaller on the Snap-On cart & in a slightly different location on the lid. So the top of hinge needs to be drilled out to fit the HF cart & needs a spacer. Bottom hole on the hinge does not matter cause you need to drill a new hole on the HF cart. The Snap-On cart uses clevis & cotter pins to attach the hinges, this allows you to quickly disconnect them so you can flip the lid all the way down to the back of the cart.

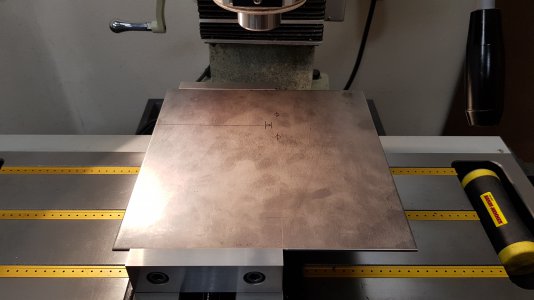

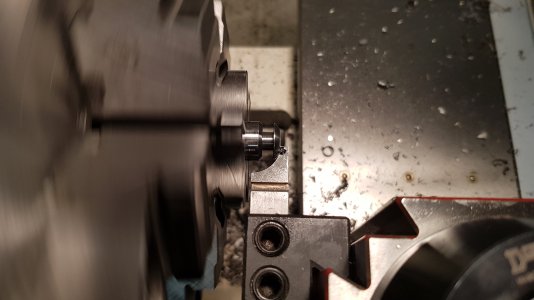

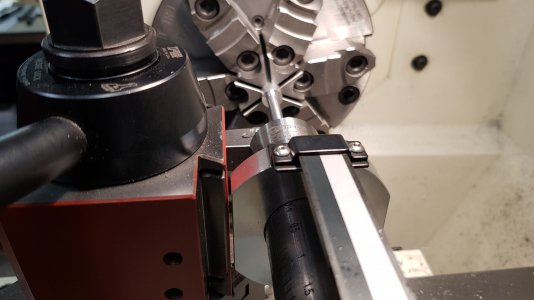

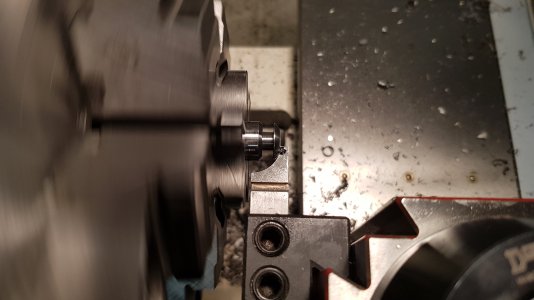

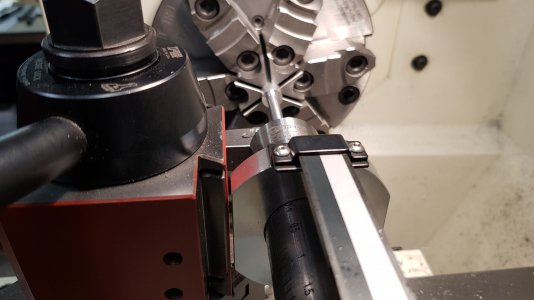

I decided to use the same mounting method. The SO hinges came with all the hardware but of course I couldn't use the included clevis pins. I had no idea clevis pins were so expensive in small quantities. I also couldn't find the sizes I needed. Don't know why I even bothered searching for them. I ended up making my own clevis pins out of 304 & spacers out of delrin.

They weren't hard to make but the 2 smaller pins were a bit challenging to hold to machine the radiused heads cause they were so short & had clearance issues. Luckily I was just barely able to get it done with what I had but much to close for comfort. I swear things looked much closer in person than they do in these pics!

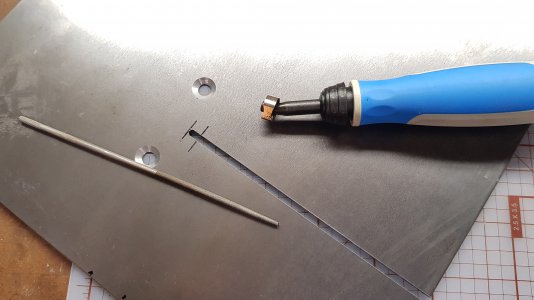

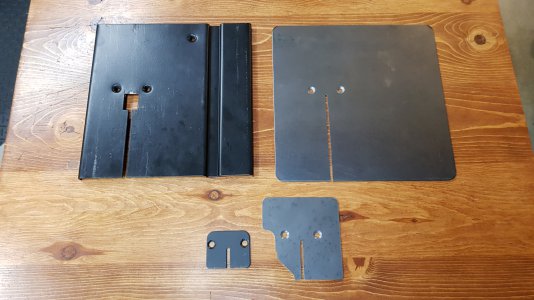

Another common mod is to modify the drawer locks. When you close the lid it pushes down 2 bars that latches on the back of the drawers. I wanted to be able to open the drawers without having to open the lid. Most people just cut the top of the bars off with a multi tool or something & call it a day. Of course I like to do things the hard way.

I drilled out the rivets holding the covers for the latching bars. Cut them on the bandsaw, deburred, painted, then reinstalled & riveted the covers back on. I cut them so they sit just below the covers. I then stuck the cut off pieces back into the caps for the bars that way if I do ever want to lock the drawers I can just simply put the caps back on. I did this to both carts.

I know, nothing really exciting to see here but I'm very happy with these mods & wanted to share. Thanks for looking!

The mounting hole size is smaller on the Snap-On cart & in a slightly different location on the lid. So the top of hinge needs to be drilled out to fit the HF cart & needs a spacer. Bottom hole on the hinge does not matter cause you need to drill a new hole on the HF cart. The Snap-On cart uses clevis & cotter pins to attach the hinges, this allows you to quickly disconnect them so you can flip the lid all the way down to the back of the cart.

I decided to use the same mounting method. The SO hinges came with all the hardware but of course I couldn't use the included clevis pins. I had no idea clevis pins were so expensive in small quantities. I also couldn't find the sizes I needed. Don't know why I even bothered searching for them. I ended up making my own clevis pins out of 304 & spacers out of delrin.

They weren't hard to make but the 2 smaller pins were a bit challenging to hold to machine the radiused heads cause they were so short & had clearance issues. Luckily I was just barely able to get it done with what I had but much to close for comfort. I swear things looked much closer in person than they do in these pics!

Another common mod is to modify the drawer locks. When you close the lid it pushes down 2 bars that latches on the back of the drawers. I wanted to be able to open the drawers without having to open the lid. Most people just cut the top of the bars off with a multi tool or something & call it a day. Of course I like to do things the hard way.

I drilled out the rivets holding the covers for the latching bars. Cut them on the bandsaw, deburred, painted, then reinstalled & riveted the covers back on. I cut them so they sit just below the covers. I then stuck the cut off pieces back into the caps for the bars that way if I do ever want to lock the drawers I can just simply put the caps back on. I did this to both carts.

I know, nothing really exciting to see here but I'm very happy with these mods & wanted to share. Thanks for looking!

)

)