- Joined

- Oct 16, 2019

- Messages

- 6,576

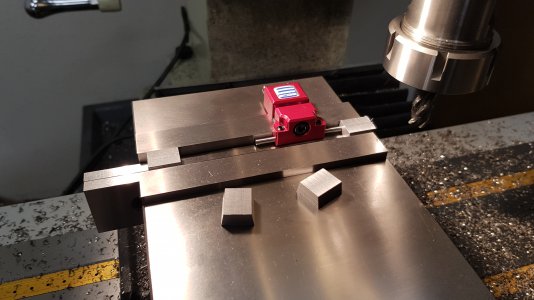

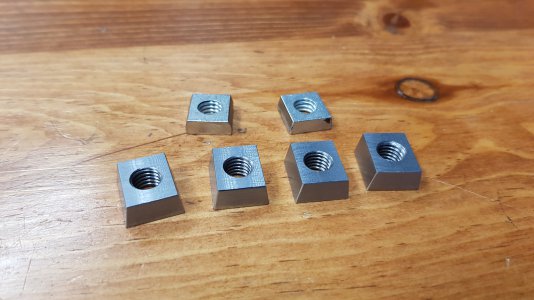

I used the horizontal table on my new-to-me 4x6 and was shall we say, less than overwhelmed by its quality and function.

I'll definitely be borrowing your ideas if I may. Would you be willing to share your CAD file

I'll definitely be borrowing your ideas if I may. Would you be willing to share your CAD file