- Joined

- Jan 2, 2014

- Messages

- 8,852

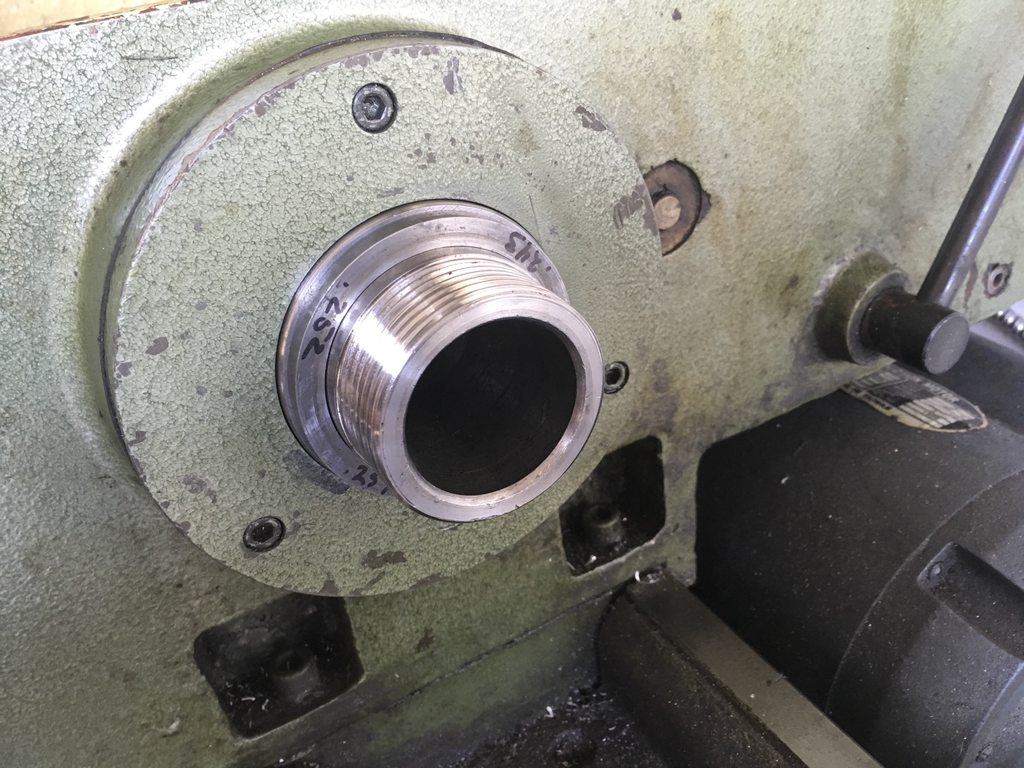

I got the runout down to maybe 0.0002", but that could be from a sloppy cut on my part. I'm not experienced enough yet to make a clean cut. I'm sure my cutter angle and feed rate are all wrong.

two tenths runout?

can't be too much you're doing wrong!

-brino