-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Precision Mathews PM1340GT Arrival

- Thread starter zmotorsports

- Start date

-

- Tags

- mike's pm1340gt

- Joined

- Mar 12, 2014

- Messages

- 1,531

Hey Mike,

I followed your posts on your new machines. I have been on the fence about purchasing some machines but, after following you through your posts. I have decided to order from Matt. I am purchasing a PM 1340gt and a PM 935 T-S. So thank you for the good reviews. Do you have a schematic of your wiring for the VFD on your lathe? I could use alittle help in that area. I do not have the machines yet maybe February or March. and what model of the WJ200 are you using?

Thanks

JD

JD, the Hitachi VFD I am using is a WJ200-015SF.

Glad to hear that you will be ordering these machines, they are very nice and I am very pleased with both of them. If you haven't checked out the youtube videos that I did on them they may be helpful. Take note that I am NOT an actor nor a professional video maker so be gentle. They are under my "zmotorsports" channel on youtube.com.

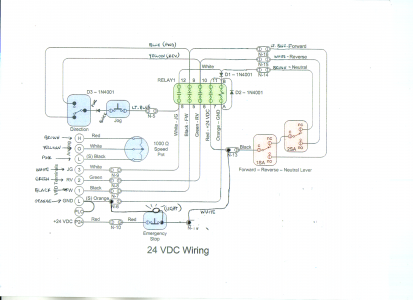

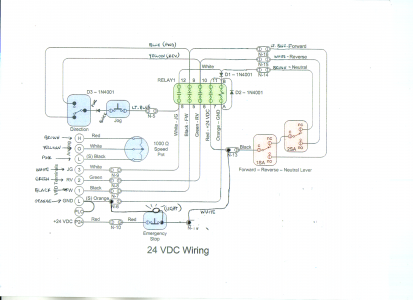

Here is a wiring schematic that I modified to show the way I wired my PM1340GT up.

I hope that will help you.

- Joined

- Mar 12, 2014

- Messages

- 1,531

Mike:

What type of oil or oils are recommended for the Norton style QCGB?

Thanks,

Steve

In the headstock I am running AW68 hydraulic oil. I also put some in a squirt can and pull the plug on occassion to squirt some onto the felt above the Norton QCGB so it can drip down onto the gears as they are turning. I use Vactra #2 way oil in a squirt can to apply to the oilers on the carriage and on the bed ways.

- Joined

- Mar 12, 2014

- Messages

- 1,531

I noticed on the Quality Machine Tools site they have a 1440E-LB for basically the same price, whats the major differences.

Tim

Biggest difference being the 1340GT is Taiwanese and the 1440E-LB is mainland China. Other than that a little larger swing and I beleive the 1440E-LB is a 2" spindle bore whereas the 1430GT is 1-9/16".

- Joined

- Jun 12, 2014

- Messages

- 4,822

I noticed on the Quality Machine Tools site they have a 1440E-LB for basically the same price, whats the major differences.

Tim

Other than the basic swing and bed length, there are probably more differences then similarities when reviewing the specs. The 1440E-LB probably requires more use of change gears. The price and accessories of the 1440E-LB is pretty attractive at this point, but something like the Grizzly G0709 is equipped/priced similar to the PM1440. It has a wider threading ability and does not require change gears for imperial threads.

Most folks I have read, purchased the 1340GT with the preferred package:

With Preferred Equipment Lathe Package

PM-1340GT $5599.00

· 6" High Precision 3 Jaw Chuck

· Micrometer Carriage Stop

· 8" High Precision 4 Jaw Chuck

· Halogen Work Light

· 1/2" Drill Chuck with MT3 Arbor and Key

· Precision Live Center, MT#3

Below are the specifications of the 1340GT base model:

Machine Standard Features and Equipment:

PM-1340GT Main Features

· Highest Quality Lathe, Made in TAIWAN

· Large 1-9/16” Spindle Bore clear through spindle for through-headstock work

· Short Spindle Length, only 14", perfect for gunsmithing work

· Extra thick spindle wall for extra rigidity, almost double most other machines in this size

· Power feed on Carriage, and Cross Slide, both left and right, and in and out, for both turning and

facing operations with automatic feed. Allows for the best surface finish in all directions.

· Induction Hardened and Precision Ground Bed Ways to resist wear and give a long service life

· All gears and shafts in headstock hardened and precision ground for long life and extremely quiet

running

· Large diameter thick tail stock quill for more rigid and accurate tail stock operations

· Removable Gap for larger diameter work

· High quality electronics used throughout machine

· Slip Clutch on feed rod, to help prevent overloading damage of feeds and allow the use of a solid

carriage stop for repetitive work

· Precision Tapered Roller Bearings used in spindle, for the ultimate in long life, high precision, and

best surface finishes. Guaranteed Run Out +/- .0001" for ultimate precision

· Inch AND Metric thread cutting ability is a standard feature

· True INCH PITCH main lead screw, cross feed, and compound lead screws make it easy to use

for the INCH measurement System, yet still has the Metric readings on dials for the ultimate in

versatility for any job that may come about

· Splash oil bath lubrication in Headstock, and Apron, for efficient lubrication, and long life, yet

simple and reliable, and does not require any filter changes or pump maintenance as with oil pump

lubrication systems. Also no risk of losing oil flow to expensive parts as there can be with pump

lubricated systems

· Only Extremely High Precision Spindle Bearings are used, FAG, NSK, NTN, or NACHI

· Locking Tang in tail stock is provided

· Longest in class, 3 Year Warranty

With Preferred Equipment Lathe Package

PM-1340GT $5599.00

· 6" High Precision 3 Jaw Chuck

· Micrometer Carriage Stop

· 8" High Precision 4 Jaw Chuck

· Halogen Work Light

· 1/2" Drill Chuck with MT3 Arbor and Key

· Precision Live Center, MT#3

Below are the specifications of the 1340GT base model:

Machine Standard Features and Equipment:

PM-1340GT Main Features

· Highest Quality Lathe, Made in TAIWAN

· Large 1-9/16” Spindle Bore clear through spindle for through-headstock work

· Short Spindle Length, only 14", perfect for gunsmithing work

· Extra thick spindle wall for extra rigidity, almost double most other machines in this size

· Power feed on Carriage, and Cross Slide, both left and right, and in and out, for both turning and

facing operations with automatic feed. Allows for the best surface finish in all directions.

· Induction Hardened and Precision Ground Bed Ways to resist wear and give a long service life

· All gears and shafts in headstock hardened and precision ground for long life and extremely quiet

running

· Large diameter thick tail stock quill for more rigid and accurate tail stock operations

· Removable Gap for larger diameter work

· High quality electronics used throughout machine

· Slip Clutch on feed rod, to help prevent overloading damage of feeds and allow the use of a solid

carriage stop for repetitive work

· Precision Tapered Roller Bearings used in spindle, for the ultimate in long life, high precision, and

best surface finishes. Guaranteed Run Out +/- .0001" for ultimate precision

· Inch AND Metric thread cutting ability is a standard feature

· True INCH PITCH main lead screw, cross feed, and compound lead screws make it easy to use

for the INCH measurement System, yet still has the Metric readings on dials for the ultimate in

versatility for any job that may come about

· Splash oil bath lubrication in Headstock, and Apron, for efficient lubrication, and long life, yet

simple and reliable, and does not require any filter changes or pump maintenance as with oil pump

lubrication systems. Also no risk of losing oil flow to expensive parts as there can be with pump

lubricated systems

· Only Extremely High Precision Spindle Bearings are used, FAG, NSK, NTN, or NACHI

· Locking Tang in tail stock is provided

· Longest in class, 3 Year Warranty