- Joined

- Mar 26, 2018

- Messages

- 8,490

I have all the materials.

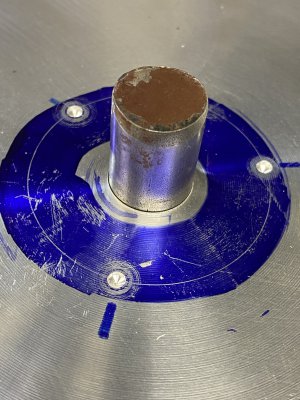

The idea is to mount this 90 RPM drive motor on the 1/2” aluminum plate. There will be an 8” lapping disc that will register on a hub on the wheel. Magnets will hold the disc to the plate.

An adjustable tilt platen will allow for precise angles to grind high speed tool, carbide blades for scraping or brazed carbide cutting tools.

The discs come in grits from 250 to 2,000 grit as far as I know.

There will be an off switch and a forward and reverse switch.

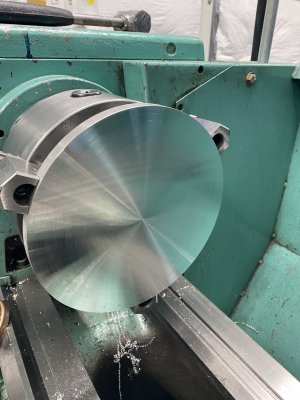

I found the motor after a long search on EBay. It’s new, made in The States and I paid less than $160 delivered, I think. The keyed shaft is 5/8”. I already made the arbor flange to mount the main wheel.

Concentricity is the main focus. I think I have a good plan. We’ll see.

Thank you, Ulma Doc, aka Mike Walton and Donald Yungling for the inspiration.

I’ll post as I make progress.

I made a little progress today.

Sammy, the dog, decided to chew up some sprinkler lines. That took up some time.

The idea is to mount this 90 RPM drive motor on the 1/2” aluminum plate. There will be an 8” lapping disc that will register on a hub on the wheel. Magnets will hold the disc to the plate.

An adjustable tilt platen will allow for precise angles to grind high speed tool, carbide blades for scraping or brazed carbide cutting tools.

The discs come in grits from 250 to 2,000 grit as far as I know.

There will be an off switch and a forward and reverse switch.

I found the motor after a long search on EBay. It’s new, made in The States and I paid less than $160 delivered, I think. The keyed shaft is 5/8”. I already made the arbor flange to mount the main wheel.

Concentricity is the main focus. I think I have a good plan. We’ll see.

Thank you, Ulma Doc, aka Mike Walton and Donald Yungling for the inspiration.

I’ll post as I make progress.

I made a little progress today.

Sammy, the dog, decided to chew up some sprinkler lines. That took up some time.

Attachments

-

EBB5EF3F-2957-42BB-8158-10141A8D083E.jpeg1.9 MB · Views: 222

EBB5EF3F-2957-42BB-8158-10141A8D083E.jpeg1.9 MB · Views: 222 -

BCD92844-A1CB-449D-A715-BD7DF9838F22.jpeg791.5 KB · Views: 215

BCD92844-A1CB-449D-A715-BD7DF9838F22.jpeg791.5 KB · Views: 215 -

5F247F80-7955-43AC-B8A8-84B8D48EBB68.jpeg775.3 KB · Views: 472,982

5F247F80-7955-43AC-B8A8-84B8D48EBB68.jpeg775.3 KB · Views: 472,982 -

90D5AB1C-5313-4E71-AF54-D768AC7EF37D.jpeg741.2 KB · Views: 175

90D5AB1C-5313-4E71-AF54-D768AC7EF37D.jpeg741.2 KB · Views: 175 -

12E23409-60DF-4B2A-B4E6-98B5BB56B40E.jpeg888.1 KB · Views: 186

12E23409-60DF-4B2A-B4E6-98B5BB56B40E.jpeg888.1 KB · Views: 186

Last edited: