- Joined

- Mar 26, 2018

- Messages

- 8,407

I cut the pockets over sized and left about .010" in depth for epoxy. Between the pocket pilot hole and the sides of the magnet, I hope to have enough holding power for the life of the tool.Sorry, didn’t mean to cause you grief. Looks like you’re good to go, maybe the volume wasn’t sufficient enough to be able move around. I just remember being totally baffled trying to figure out why my epoxy was climbing uphill! Glad it worked for you Jeff

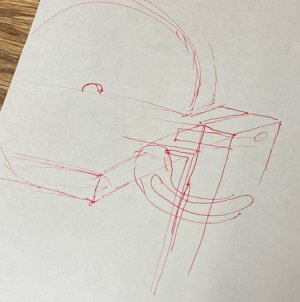

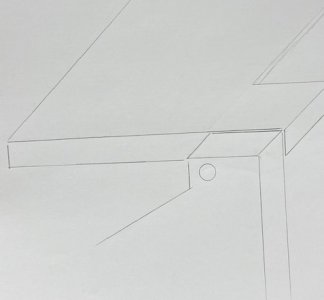

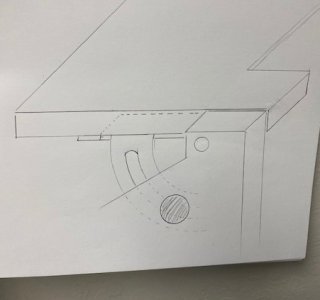

Thinking about the table size and the tilting method. I draw it in a doodle first then clean it up.

I call it my CAD program. You know, Conceptualize, Adjust and Dream it up.

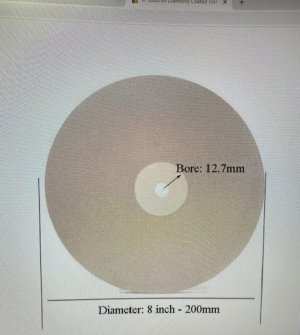

I know there's probably a dozen or more ways to do this. I'm concentrating on the pivot point. My gut tells me it should be just off the face of the disc. Of course the table will be able to slide in and out but I'm designing it with this idea in mind.

Aluminum and heavy sheet metal.

Attachments

Last edited: