- Joined

- Sep 1, 2020

- Messages

- 549

@tonydi glad to hear you made some progress. Let me try to answer your questions and see if we can get you there.

1. Finishing lines can be done by double clicking at the end of your line or by hitting escape. For me the double click is less consistent if I bounce the mouse when doing it. I am in the habit of using escape. By default the line command is set to chain lines together. There are likely other ways to end them those are what I use. Also when sketching on the part it does not technically fill in the other lines it is just that Fusion should recognize when you are sketching up to other lines vs sketching in the open and when you go up to other lines they will “close” the shape.

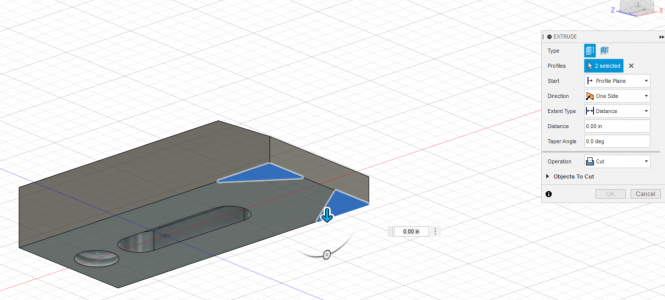

2. Very likely your issue is related to the lines. My understanding is Fusion is designed to allow you to select any “closed” shape and manipulate it. If you are not able to select those triangles then it would seem they are not fully “closed”. Couple ideas. Are you sketching on the surface of your part or on the plane (top, bottom, left etc. ) or did your point not snap to the edge, line not snap to point creating an opening? Zoom in and see and tip the model a bit to ensure that triangle is a complete triangle.

I hope that gives you some thoughts to try or someone else can jump in as we narrow your issues.

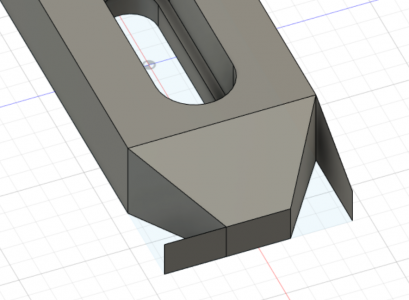

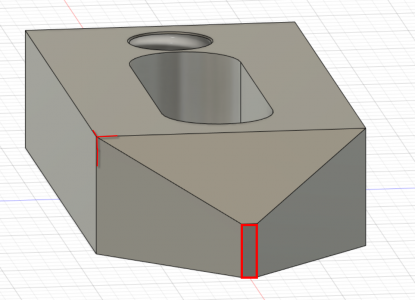

I had some other feedback on my video and the points are not required, you can draw and dimension the lines directly in a sketch and save some steps. Instead of the offset plane I could have selected the remaining body of the clamp on the side behind the newly created beveled front corner and still sketched out on that flat plane to make the cut across the top.

Hang in there, I am sure we can help you clear this up.

1. Finishing lines can be done by double clicking at the end of your line or by hitting escape. For me the double click is less consistent if I bounce the mouse when doing it. I am in the habit of using escape. By default the line command is set to chain lines together. There are likely other ways to end them those are what I use. Also when sketching on the part it does not technically fill in the other lines it is just that Fusion should recognize when you are sketching up to other lines vs sketching in the open and when you go up to other lines they will “close” the shape.

2. Very likely your issue is related to the lines. My understanding is Fusion is designed to allow you to select any “closed” shape and manipulate it. If you are not able to select those triangles then it would seem they are not fully “closed”. Couple ideas. Are you sketching on the surface of your part or on the plane (top, bottom, left etc. ) or did your point not snap to the edge, line not snap to point creating an opening? Zoom in and see and tip the model a bit to ensure that triangle is a complete triangle.

I hope that gives you some thoughts to try or someone else can jump in as we narrow your issues.

I had some other feedback on my video and the points are not required, you can draw and dimension the lines directly in a sketch and save some steps. Instead of the offset plane I could have selected the remaining body of the clamp on the side behind the newly created beveled front corner and still sketched out on that flat plane to make the cut across the top.

Hang in there, I am sure we can help you clear this up.