I don't claim to be an expert on gears. I design medical devices and fixturing and often use gearing in my designs so I have some practical experience using them.

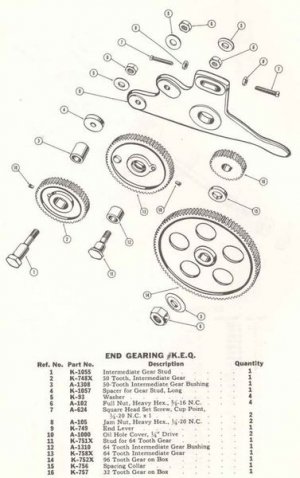

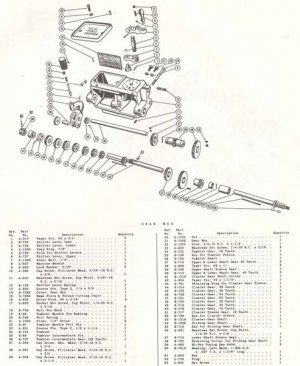

A 16 tooth spur gear with 72 teeth has a PD that is 4.5" and an OD that is 4.625"

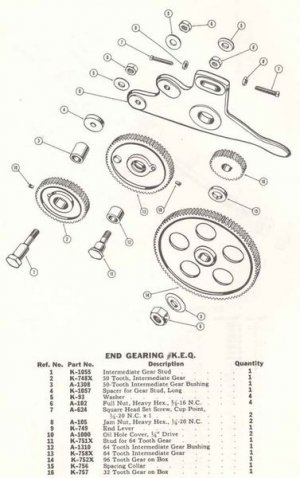

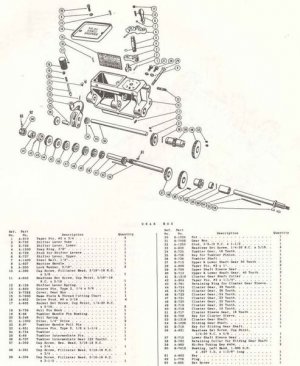

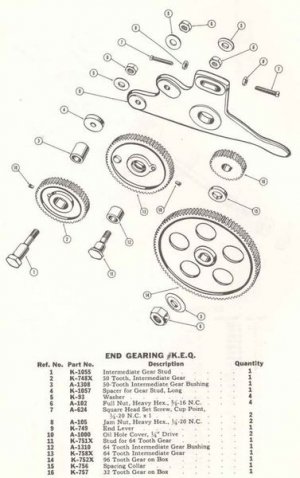

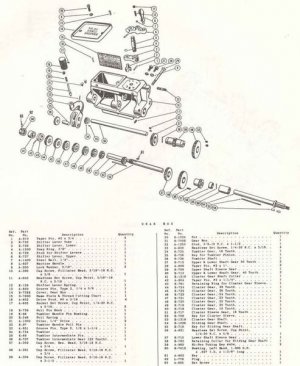

73 teeth does not make sense. I have owned several old lathes and I don't see how the correct feed ratios can be obtained with a 73 tooth gear in the feed gear train.

Charlie

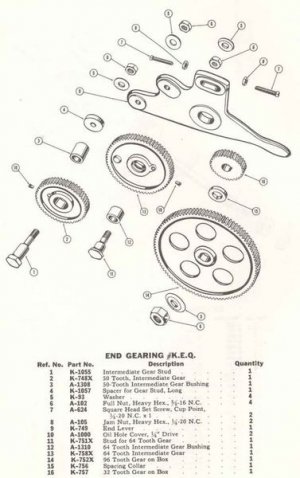

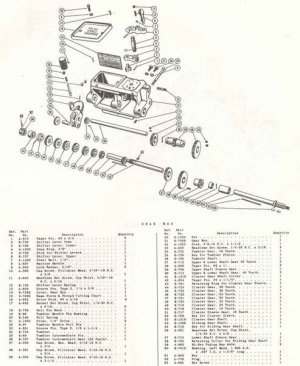

A 16 tooth spur gear with 72 teeth has a PD that is 4.5" and an OD that is 4.625"

73 teeth does not make sense. I have owned several old lathes and I don't see how the correct feed ratios can be obtained with a 73 tooth gear in the feed gear train.

Charlie