It certainly has 72 teeth + one missing makes 73. I use to have a Sheldon like yours but it didn't have any gear issues so I have no idea what gearing it had.

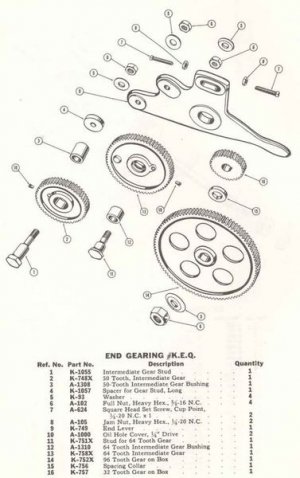

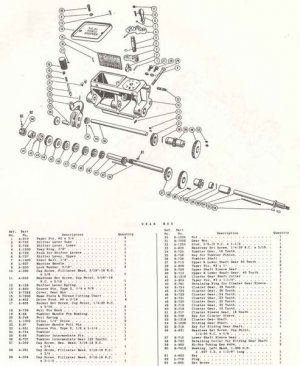

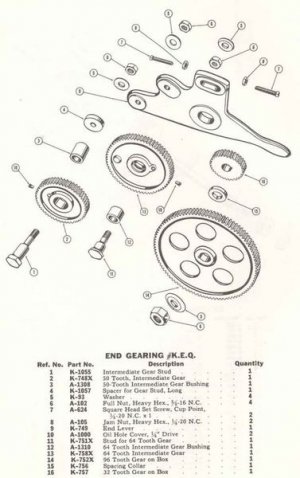

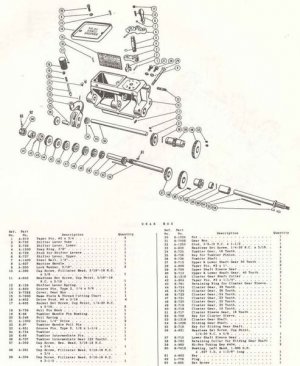

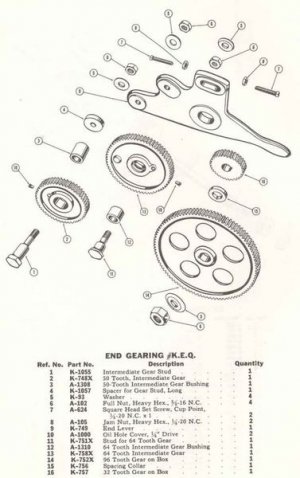

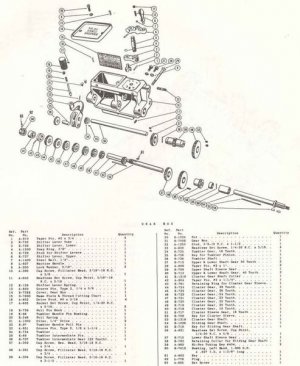

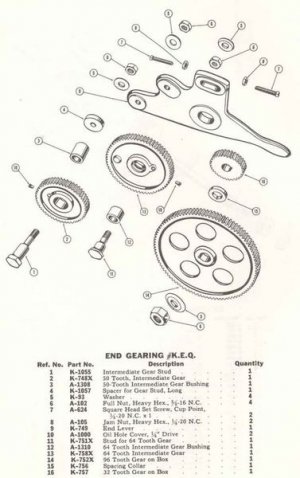

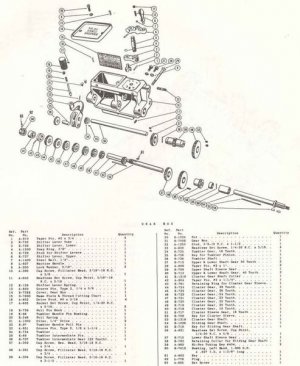

I went out to my shop and went through my old manuals and came across manuals for Sheldon 10", 11" and 12" lathes.

I think this information may be helpful.

Charlie

The 2 pages show Sheldon gear numbers. I noticed that the picture showing the end gear train shows a gear number listed. Does the one with the broken tooth have a "K" number on it? Based on the numbers listed, I suspect the broken gear does not belong to the lathe.