- Joined

- Aug 26, 2014

- Messages

- 132

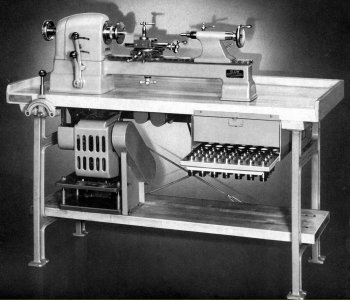

That lathe is just begging to be put back to use, not much real deep rusting by the pictures. Lots of cleaning and polishing needed to bring her back , painting seems like the hardest thing on it . Getting her stripped and primed will take some time for sure but ,looks worth it.

These are the options I've heard so far–coming from two electricians, you guys and a tool and die maker friend of mine:

A. Keep the motor it's got and get a static phase convertor (the electricians I talked to don't think the price of a VFD is warranted with this machine, and my expected uses) to go with it; since it's only .75 Hp, it's not doing enough damage for the unbalanced power to damage it.

- Would require either a transformer and great care not to fry my 12 AWG wire or a new 220 circuit to power it. (Not thrilled about that.)

B. Swap in a 1phase motor.

- Would require a new mounting setup

- It's hard to find a 1 phase 1730/860 motor, the fellows at Grainger said I'd be more likely to find a 1730/1140 motor which would leave my "slow" speed as not terribly slow.

- I'd need to make a new pulley since they don't make many 1phase motors with 3/4" shanks.

C. Have the motor rewound to my desired phase and speed specs

- Best option so far: guarantees I've got a motor that works (and not an old dud) and it'll work without redoing my whole house.

- Do a cost benefit analysis of $/functionality and decide that the most efficient thing for me is to just pull off the turret, adapt it to one of my lathes I have and get rid of the machine.

- This is the only option that doesn't require replacing the belts, the motor and/or circuitry and…

- Trying to dismantle or otherwise lug the thing up two flights of stairs. (On a second floor building with no elevator.)