Hey all,

I am refurbishing a Bridgeport mill, and I want to convert the older-style oil zerks to a newer one-shot oiler. So I bought an oiler that looks like this one from Ebay:

And specifically has the connectors which are supposed to screw into the Bridgeport that looks like this (I measure this at metric 5.7 mm x 1 mm pitch -- probably supposed to be M6 x 1):

Unfortunately, I didn't catch that this connector thread would be different from the ones from my Bridgeport that look like this:

So what I need is an adapter. Something like this:

So my goal is to figure out the specifications of the original threads and the new threads, and see if I can purchase or manufacture a connector.

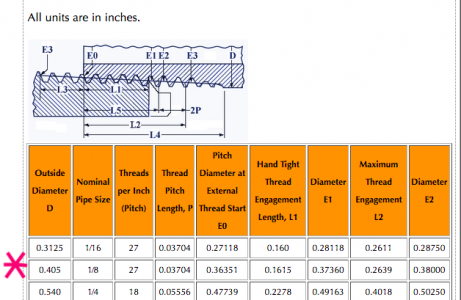

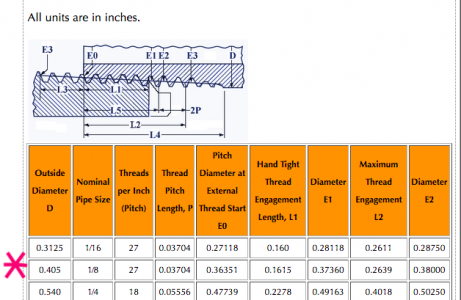

I have tried to figure out the threads of the original zerks. I notice that the thread is tapered. And with my thread gauge, it seems to be about 28 TPI, though it doesn't fit at neatly as I would like. Perhaps the thread profile is different. At it's widest, I measure 0.400", and it narrows to 0.365" at the base. So I am wondering if this is a NPT pipe style thread. I found this link: https://www.engineersedge.com/hardware/taper-pipe-threads.htm which lists an NPT "1/8"-27 thread with external diameter of 0.405".

I also found this zerk set here:

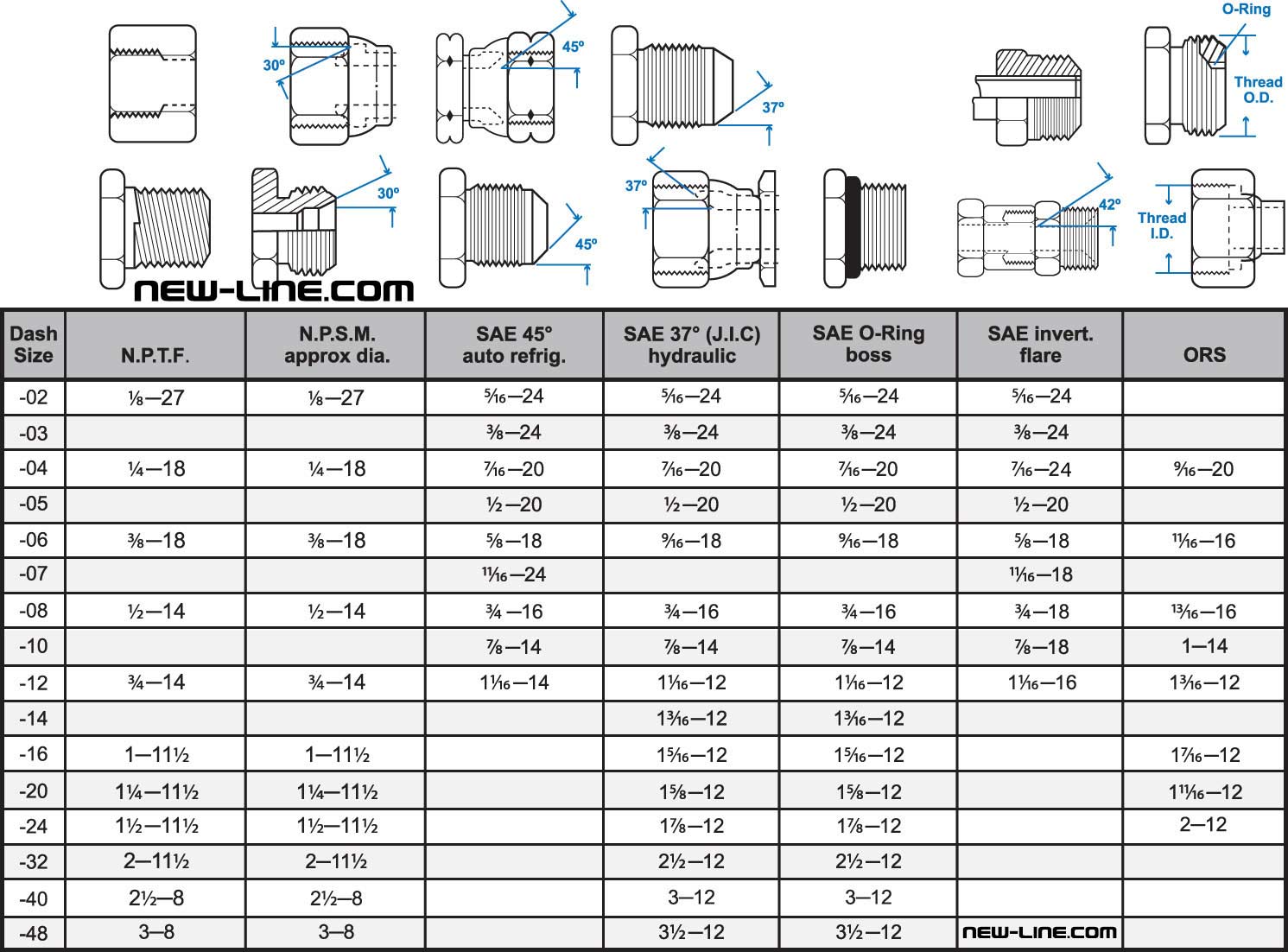

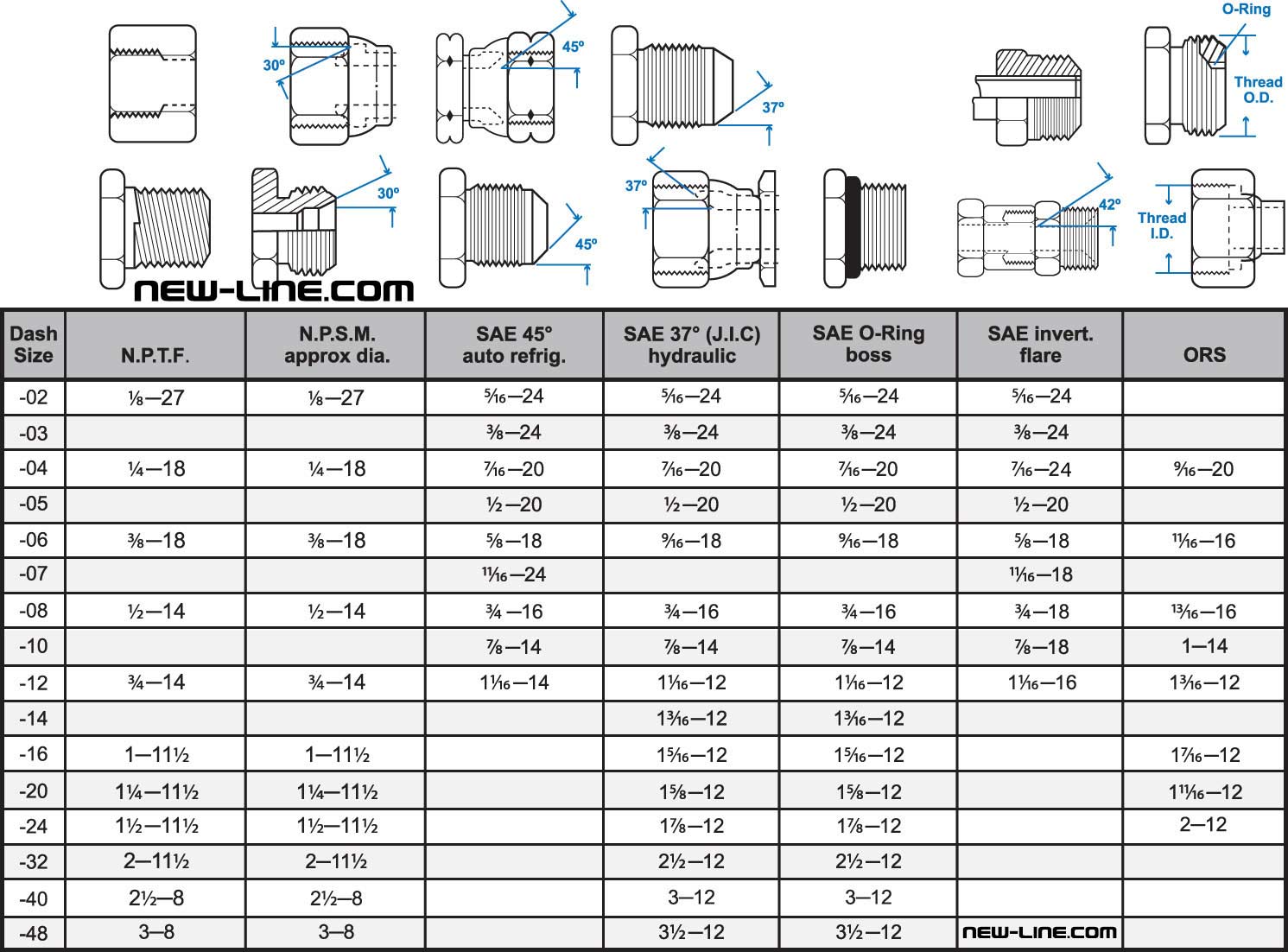

which shows zerks that are SAE or PTF type threads.

And this chart from here shows various SAE, and NPTF fittings:

I am thinking if I could get a grease fitting cap, that I could then tap this for the M6x1 thread to make an adapter. I found here a plug for 1/8-27 PTF that might work.

As an additional complication, this is the location of the zerks on the front of my saddle (stripped of paint)

This is going to be very awkward to have oil tubes sticking out before curving back to the hub. I am going to see if I could cap these off and connect a new channel from inside.

QUESTIONS:

Kevin T

I am refurbishing a Bridgeport mill, and I want to convert the older-style oil zerks to a newer one-shot oiler. So I bought an oiler that looks like this one from Ebay:

And specifically has the connectors which are supposed to screw into the Bridgeport that looks like this (I measure this at metric 5.7 mm x 1 mm pitch -- probably supposed to be M6 x 1):

Unfortunately, I didn't catch that this connector thread would be different from the ones from my Bridgeport that look like this:

So what I need is an adapter. Something like this:

So my goal is to figure out the specifications of the original threads and the new threads, and see if I can purchase or manufacture a connector.

I have tried to figure out the threads of the original zerks. I notice that the thread is tapered. And with my thread gauge, it seems to be about 28 TPI, though it doesn't fit at neatly as I would like. Perhaps the thread profile is different. At it's widest, I measure 0.400", and it narrows to 0.365" at the base. So I am wondering if this is a NPT pipe style thread. I found this link: https://www.engineersedge.com/hardware/taper-pipe-threads.htm which lists an NPT "1/8"-27 thread with external diameter of 0.405".

I also found this zerk set here:

which shows zerks that are SAE or PTF type threads.

And this chart from here shows various SAE, and NPTF fittings:

I am thinking if I could get a grease fitting cap, that I could then tap this for the M6x1 thread to make an adapter. I found here a plug for 1/8-27 PTF that might work.

As an additional complication, this is the location of the zerks on the front of my saddle (stripped of paint)

This is going to be very awkward to have oil tubes sticking out before curving back to the hub. I am going to see if I could cap these off and connect a new channel from inside.

QUESTIONS:

- Does anyone know the nominal specifications or dimensions, or thread style of the oil zerks used in Bridgeport mills?

- Has anyone seen any adapters such as I am looking for already made up?

- Any recommendations for options for those front-facing oil ports?

- Any other recommendations?

Kevin T