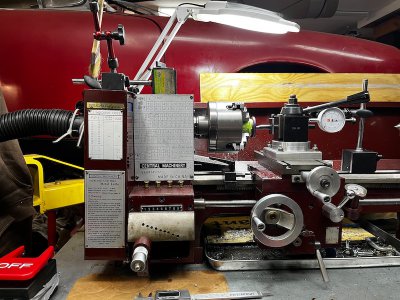

Hey everyone. I have possibly the cheapest 7x14 mini lathe that I got on Amazon. It claims to have a 550W motor and it's just horribly under-powered. It's also, unsurprisingly, about as rigid as a wet paper towel. I knew it would be when I bought it but it was the only one in my budget at the time (like $500).

I've used the crap out of it and made some useful parts, but I've always planned on upgrading eventually. So I've been looking around and I see that Grizzly is having a sale on most of their site.

I'm looking at buying the G4000 lathe: https://www.grizzly.com/products/grizzly-9-x-19-bench-lathe/g4000

I know it has awesome features that my 7x14 doesn't have, like the gear box, steady rest, follow rest, threading dial, better tailstock, etc. But I'm not sure how the power and rigidity compares to the crappy 7x14.

My question is: How much better would this be over the cheap 7x14 in terms of power and rigidity?

I've used the crap out of it and made some useful parts, but I've always planned on upgrading eventually. So I've been looking around and I see that Grizzly is having a sale on most of their site.

I'm looking at buying the G4000 lathe: https://www.grizzly.com/products/grizzly-9-x-19-bench-lathe/g4000

I know it has awesome features that my 7x14 doesn't have, like the gear box, steady rest, follow rest, threading dial, better tailstock, etc. But I'm not sure how the power and rigidity compares to the crappy 7x14.

My question is: How much better would this be over the cheap 7x14 in terms of power and rigidity?