- Joined

- Aug 6, 2015

- Messages

- 3,908

What he ^^ said…

I came to this forum asking similar questions when I had nothing… I did not listen to the recommendations…because I did not understand them and because I thought I was never going to need anything bigger (this was for my first milling machine, a lathe was not even in my plans then)

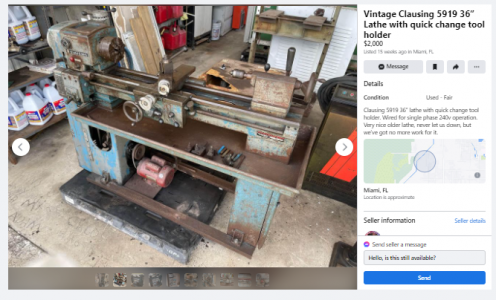

First, go for the largest lathe you can afford for the space you have… and if you can make some more space available to be able to get an even larger lathe, do it…

Quick change gear setup is awesome and DRO is what civilized people should have . Well DRO in a milling machine is a must… I still do not have those in my lathes…but plan to add them.

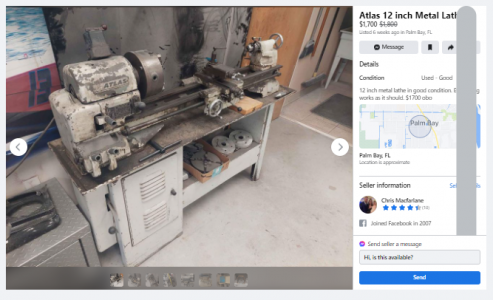

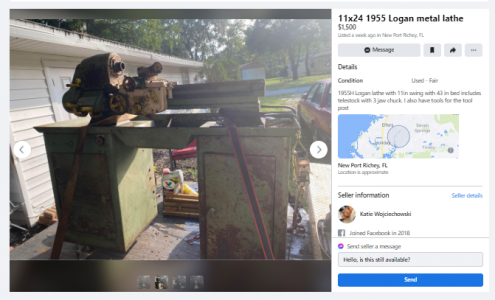

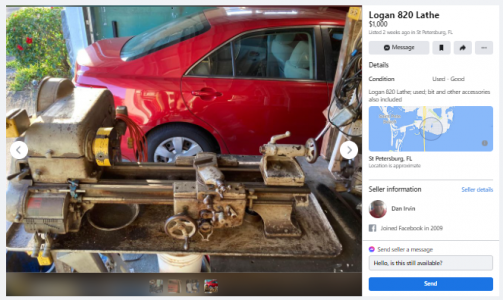

And do not discount buying use. I was on the boat that it had to be new…even order one…but I was wrong… If you armed yourself with the knowledge from the folks here, you can buy used if you know what to inspect…

I came to this forum asking similar questions when I had nothing… I did not listen to the recommendations…because I did not understand them and because I thought I was never going to need anything bigger (this was for my first milling machine, a lathe was not even in my plans then)

First, go for the largest lathe you can afford for the space you have… and if you can make some more space available to be able to get an even larger lathe, do it…

Quick change gear setup is awesome and DRO is what civilized people should have . Well DRO in a milling machine is a must… I still do not have those in my lathes…but plan to add them.

And do not discount buying use. I was on the boat that it had to be new…even order one…but I was wrong… If you armed yourself with the knowledge from the folks here, you can buy used if you know what to inspect…