- Joined

- Jul 28, 2017

- Messages

- 2,390

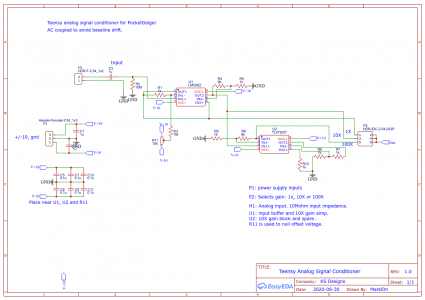

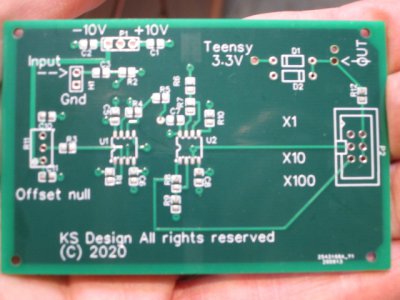

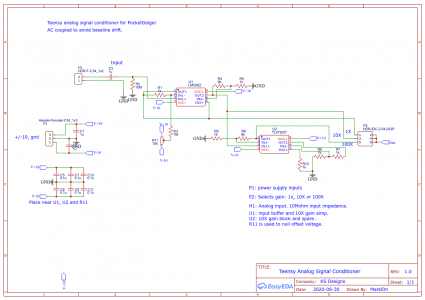

I decided to design a PCB for my pocketgeiger-to-Teensy signal-conditioning circuit. Mostly as a way to learn how to use EasyEDA. When I was using ExpressPCB I got kind of spoiled by having 4 layer PCB's available for not a lot of money so, although it's overkill, I went with a 4-layer PCB for this one. It really does make it easier to lay out boards if you can avoid all the Vcc/Vee/Gnd traces by just sinking a via down to a power or ground plane. Even with the two "extra" layers, it only cost $7 for five boards (the minimum quantity they will make). That includes silk screen and solder mask layers for the top and bottom! It cost more for the shipping than to make the darn boards! The SMT components I don't already have are on order from Mouser

Anyway, I've attached the schematic to show folks what I'm up to. There should be enough comments there to figure things out, but if not I'd be happy to clarify. I'm using the LMC662 because it should have very low current noise (Iin = 2FA @RT). The input RC time constant is 10 seconds so it won't distort the low-speed signal coming out of the pocketgeiger board. It's important to minimize baseline drift because that will affect the peak voltage, which is what the MCA uses to determine what element(s) are present.

Anyway, I've attached the schematic to show folks what I'm up to. There should be enough comments there to figure things out, but if not I'd be happy to clarify. I'm using the LMC662 because it should have very low current noise (Iin = 2FA @RT). The input RC time constant is 10 seconds so it won't distort the low-speed signal coming out of the pocketgeiger board. It's important to minimize baseline drift because that will affect the peak voltage, which is what the MCA uses to determine what element(s) are present.