Re: Easy Integration

I know I am here getting into some old-school analog, but it seems to me that for us, extremely accurate real-time integration can be done with the same opamp integrator circuit as was (maybe still is) used to control missile guidance feedback loops, Saturn 5 rocket engine gimbals, LEM landers, etc. This is just another passing notion that I thought might eliminate a whole bunch of sampling and integrating software. All the program need do is listen to the trigger, fetch the answer from ADC, and reset the integrator. The number is ready to be used.

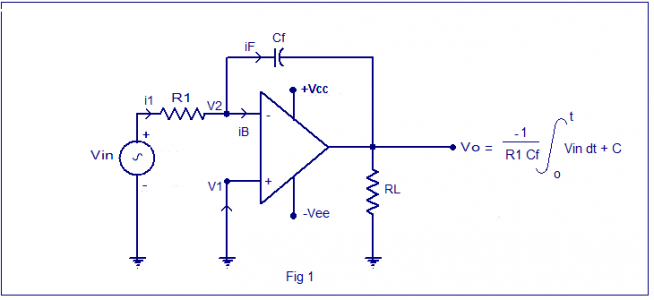

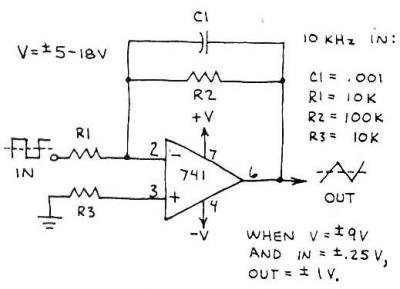

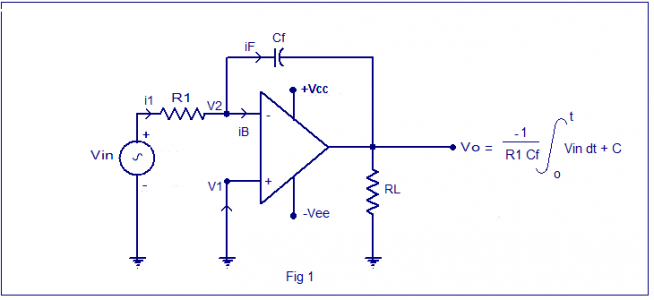

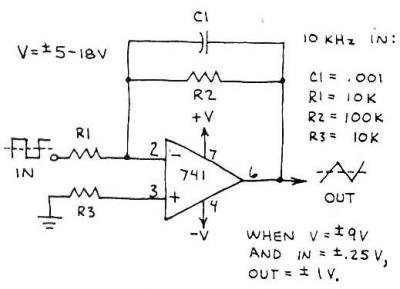

Sure - I do know that Moore's Law is reaching it's limit for for digital stuff [Ref: 1], because transistors are becoming nearly the same size as atoms, and analog computing is making a comeback , but this is much simpler stuff. An opamp integrator delivers at the speed of electrons, with infinite resolution on the time axis. If started by a trigger set a bit above the noise level, it will ride up to the value analogue of the photon energy in the pulse, effectively, the area under the curve. Follow it with an inverter buffer for a positive output. The circuit needs a FET analog reset switch for after the pulse is deemed to be over.

Opamp integrator is good for all amplified photon current pulses from TIA's, stretched or not. Yes, the final circuit will have a few more parts, there needing to be an enable-reset and all, but the bits are tiny and cost only cents. One of the simplest just uses a FET to short out the capacitor.

The low pF value capacitors seen across the feedback resistors in the Pocket Geiger amplifiers were there for stability. This is different, and such an integrator would come after the gain stages. Having a capacitor be the opamp main feedback, makes an integrator, and any resistor across it turns it into a low pass filter. For accurate computing, you make the resistance value so high it can't affect the computation, or you just don't need have any resistor there at all. For the duration the pulses have, low leakage capacitors, and special substrate materials, etc. is just not needed.

There are, of course, dozens of integrator circuits described on the internet. Obviously, they were very popular!

[Ref 1:

The Most Powerful Computers You've Never Heard Of ]