- Joined

- Aug 19, 2014

- Messages

- 225

Put a junction box in the ceiling and drop a wire down to the lathe. No wire on floor, no mess, works great.

Pushing equipment against the wall in some cases makes it harder to use and maintain.

A table saw, for instance, belongs squarely in the middle of a room.

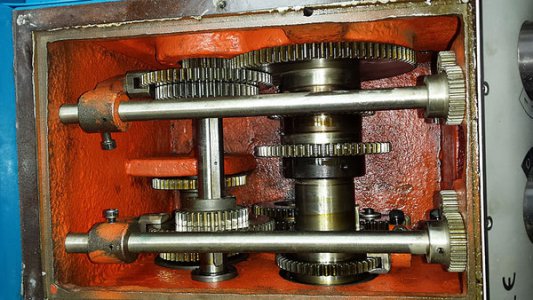

I keep coming back to the center of the work room (12x24) section of the shop. But it would also make sense to have the 30x60 steel work table in the middle of the room. So, I'm still thinking about a wall location. Just not finding one easily without major reorg of wall stuff. I bought 20A twist lock items for a drop cord, so I can go either way. Steel table if right in the pic. If I swap places I would probably have to raise that shelf and for sure re-locate all the bolt bins. Left wall is full with peg board, 48" work bench and 72" bench with the 9x20 on top.