- Joined

- Mar 12, 2014

- Messages

- 1,531

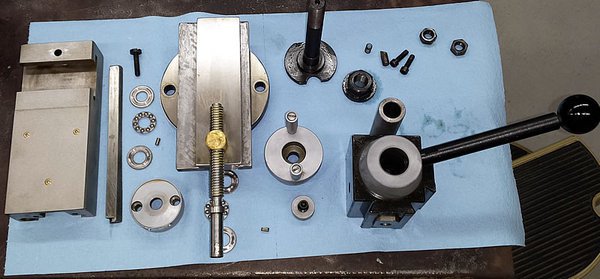

Looks like some nice progress Chris. Personally, I think the two pieces of equipment compliment each other perfectly. Bigger is not always better, especially when the needs don't justify it. I would much rather have the space and the equipment just big enough to get the tasks done. That said, the mill and lathe I have are probably larger than I really need for the majority of my work.