- Joined

- Nov 9, 2017

- Messages

- 222

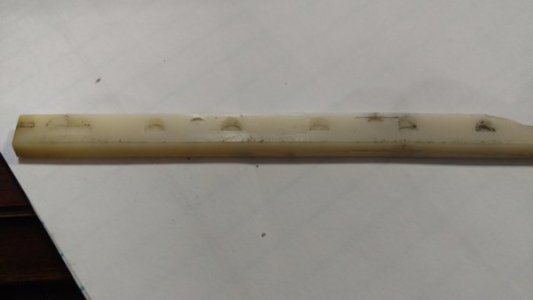

Thanks for the input guys. Given the odd cross section shape of these gibs, I don't think I can make them myself, I don't have the equipment to do that. I guess I could take them to my local machine shop and ask them to reproduce them in a metal, but they'd likely charge me $200 or so to make them (I'm guessing).

Maybe I'll just get some new plastic ones from Clausing and move on. The gib for the cross slide looks a bit deformed, so it's not so good now probably.

wa5cab - if any of these are made for sale I'd be interested in knowing.

Maybe I'll just get some new plastic ones from Clausing and move on. The gib for the cross slide looks a bit deformed, so it's not so good now probably.

wa5cab - if any of these are made for sale I'd be interested in knowing.