- Joined

- Aug 6, 2015

- Messages

- 3,886

Here you go... http://www.hobby-machinist.com/threads/my-logan-820-lathe-journey.100944/

I did not want to hi-jack the OP's thread...

Here you go... http://www.hobby-machinist.com/threads/my-logan-820-lathe-journey.100944/

...

When I took the motor mount assembly apart, it's apparent to me the support "peg" leg should be secured to the floor (previous owner had nothing secured). I note there are holes in the feet of the legs and I'm curious what you guys may have used to secure your machines to the floor, if anything? At least an anchor bolt on the peg leg? Some red heads to snug up to keep from walking or falling over during a shaker?

...

The machine has just about everything it came with, including the draw bar and collets. Looking forward to putting back together and checking as I go. Just received a black crutch foot boot to use use between the peg leg and the motor bracket.

Yes. My observation is it that it's not seen on later lathes, even prior to the 1820 vee belt change over. I suspect it was quickly determined to be an unnecessary expense for the casting, and the reversing switch made more sense for production shops. Just an opinion.Isn't that hole for the original switch ?

My 10EE has holes too. The manufacturer states they are for leveling pads. Many old shops had wood floors, and they turned out parts that won WWII. Shimming between a bed and "whatever" to level the bed is a PIA. Adjusting a pad? Two open end wrenches. If you do bolt to the floor, I suggest threaded rod so you can adjust washers on nuts and not between the bed and pan. Just my $.02Thank you for the welcome messages and responses to my couple of questions. My time is limited to work on putting back together, will be a slow process. Pressure worked OK on the adding paint, but I think I'll end up wire wheeling down the legs and pan to clean up for a nice smooth finish. I did pick up a quart of the Baby Black Seal oil enamel paint last Friday.

I've looking around for a rear splash / chip pan, but haven't found much in terms of easy cut and bolt in options. Worst case scenario, it will be some thin sheet over drywall in my garage, but would rather keep the chips in the pan as much as possible. Yeah, I could see how an auto drip pan could work too.

I was reading on the Practical Machinist site some thoughts on if machines should be bolted / secured to the floor. There was one post that was the kicker for me: the manufacturer didn't put holes in the legs for no reason. I'm thinking some 1/2" threaded anchors with a means to level each. Will have to rent a roto hammer drill when the time comes to drill the 4 holes + 1 for the peg. Trick will be picking where it will sit for a few decades, but I guess I have some time to give that thought while I start with the legs and pan.

Luckily, I found the 220V feed to my soon to be removed hot tub and can easily put in a receptacle to use the 220V 1Ph to 220V 3Ph inverter that came with lathe.

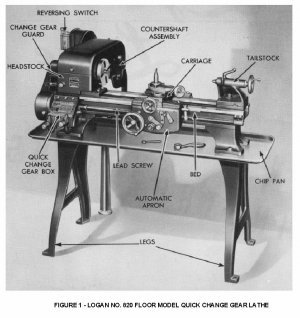

The photo isn't great and from the previous owner's shop. I just noted the gaping open rectangular space on the operator side of the headstock. Some photos of 820's have the cut out, some don't. Might this be to access the pin on the bull gear? Seemed easy enough from the 12 O'Clock position by opening the top cover, but not sure. The additional "Delta Equipment Agency" name tag makes me wonder about its roots. Maybe a retailer from 1941?