-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Member From Langley Bc Ready To Start Lathe & Mill Shopping

- Thread starter Kiwi Canuck

- Start date

- Joined

- Oct 16, 2019

- Messages

- 6,576

I guess I should update this thread so the journey is complete.

I've have had my PM 935 mill up and running for sometime, but I still need to complete the tach install, build a proper stand and buy a better vise (or maybe 2)

The lathe on the other hand sat neglected as life got busy and I've been distracted by work, family, motorcycle trips and just living life.

Sometime around Dec 1st last year, I got a list of things together that were incomplete in my life and started working on them, the lathe was on the list but it's taken till this month to get at it with a dedicated recommitment.

I studied the wiring diagram supplied by Mark Jacobs and finished up the wiring, surprisingly everything worked perfectly which was a nice feeling as it`s easy to get a diode installed backwards or miss a vital connection as I did on the mill install.

The electronic braking is outstanding, I just love that feature, also the forward reverse jog is cool.

I installed the Aloris QCTP, I took my time milling the supplied material for the T-nut and fitted it, very nice piece of kit and it works so smoothly.

View attachment 318602

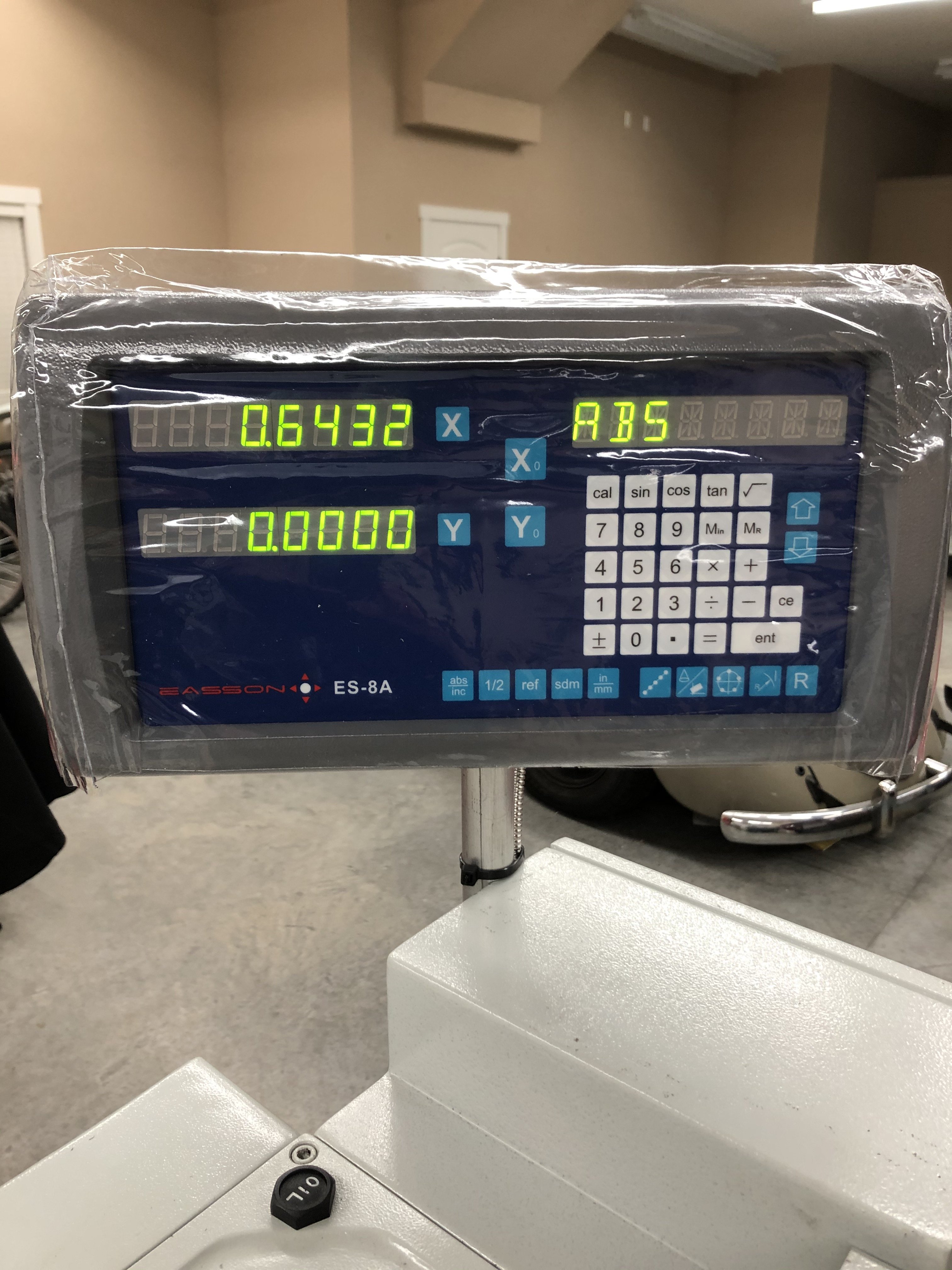

Last week I was working on mounting the DRO including the Easson display, I made a few mockups for the display and wasn`t happy with any of them, they just looked cobbled together, functional but not easy on the eyes.

On the mill I used the factory supplied bracket and arm for the display and it looks OK, but I wanted to do something better on the lathe, so I found some 1.125 aluminum round and machined a flat on one side then drilled and tapped 3 holes using the DRO line feature.

I used the same settings to make a template for drilling the side of the electrical box, clamped to the box and drilled 3 holes, once installed on the electrical box I considered how to mount the arm, and then I thought do I actually need an adjustable arm, maybe not.

So I drilled the center of the piece out using the lathe for the first time and then tapped it with a 10 X 1.5 tap, using the lathe turning the chuck with the jog button, that was easy.

After test fitting it the display sat up quite high so I drilled out about 1`` of the threads out so it could thread in further and the display sat lower, it tightened up in the exact right spot and I left it like that till I pull it apart for painting.

View attachment 318597

View attachment 318604

View attachment 318598

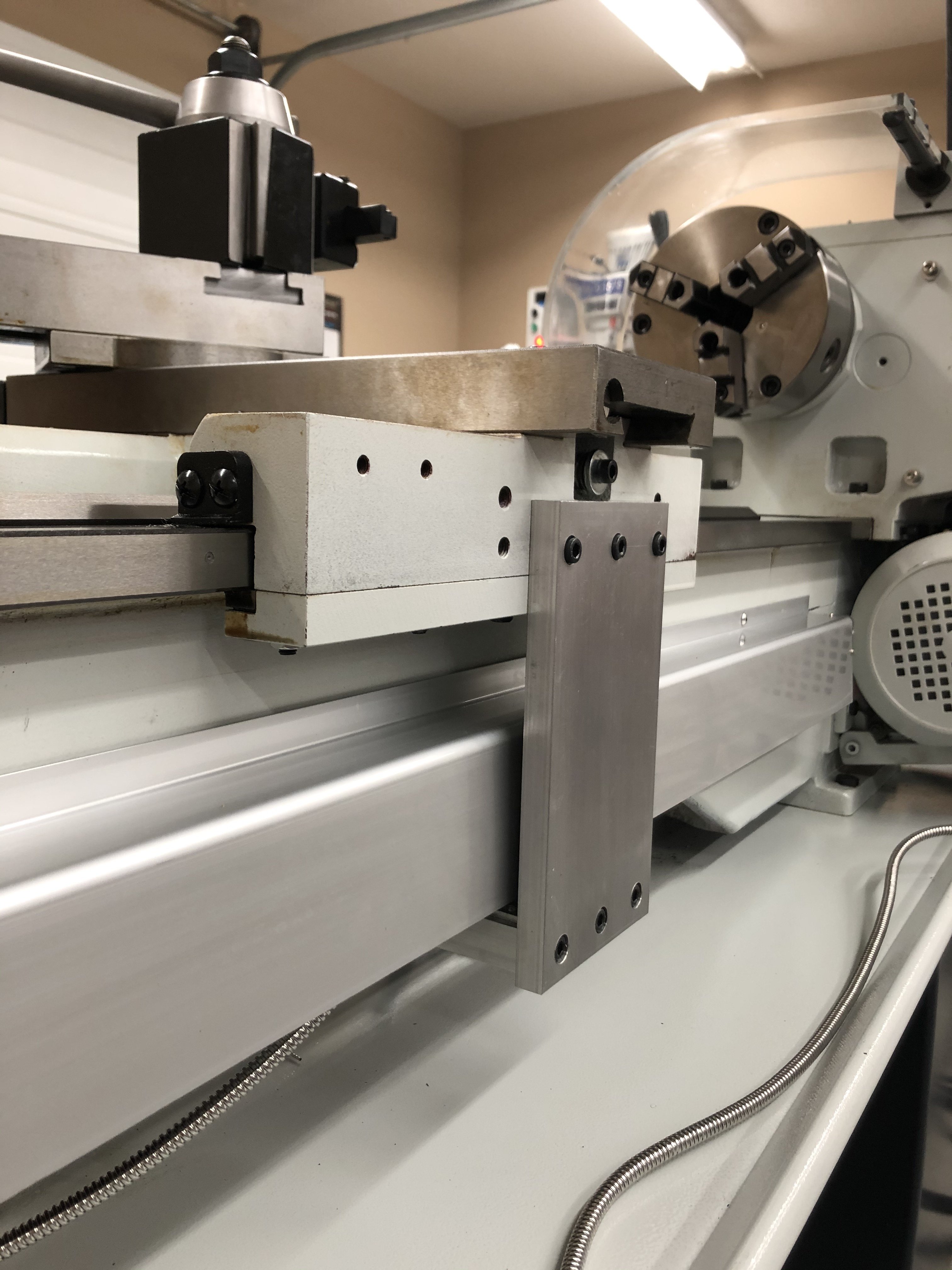

Now onto the install of the scales, this is the part that makes me sweat, drilling into the cross slide and tapping with a 6mm tap, first hole done, I usually drill one hole then align the piece and then mark the other holes with a transfer punch just in case the drill wanders a little, I get to correct for each hole this way.

View attachment 318600

This part finished, now for the scales, I``ll finish those later tonight.

View attachment 318601

I hope the bracket clears the cover as I plan on installing the covers, if not I can always mill out a bit from this bracket to make clearance.

More to come.

David.

Great install.

Is that a ‘65 Beetle?

Sent from my iPhone using Tapatalk

- Joined

- Dec 31, 2016

- Messages

- 166

Good to see you're still at it David. I basically was lazy and bought the same lathe with the DRO installed by Matt's crew but did ultimately install Mark's control system and it is SLICK I agree, that jog is so handy as is the proximity sensor for the carriage. Nice work there, we're doing much the same thing, I've knocked off some parts for my bikes, mostly fasteners that are unique and were trashed and even made a top for a triple tree to fit as set of GSXR forks on my friends cafe Racer build. The tools are great to have and one learns endlessly from them.I guess I should update this thread so the journey is complete.

I've have had my PM 935 mill up and running for sometime, but I still need to complete the tach install, build a proper stand and buy a better vise (or maybe 2)

The lathe on the other hand sat neglected as life got busy and I've been distracted by work, family, motorcycle trips and just living life.

Sometime around Dec 1st last year, I got a list of things together that were incomplete in my life and started working on them, the lathe was on the list but it's taken till this month to get at it with a dedicated recommitment.

I studied the wiring diagram supplied by Mark Jacobs and finished up the wiring, surprisingly everything worked perfectly which was a nice feeling as it`s easy to get a diode installed backwards or miss a vital connection as I did on the mill install.

The electronic braking is outstanding, I just love that feature, also the forward reverse jog is cool.

I installed the Aloris QCTP, I took my time milling the supplied material for the T-nut and fitted it, very nice piece of kit and it works so smoothly.

View attachment 318602

Last week I was working on mounting the DRO including the Easson display, I made a few mockups for the display and wasn`t happy with any of them, they just looked cobbled together, functional but not easy on the eyes.

On the mill I used the factory supplied bracket and arm for the display and it looks OK, but I wanted to do something better on the lathe, so I found some 1.125 aluminum round and machined a flat on one side then drilled and tapped 3 holes using the DRO line feature.

I used the same settings to make a template for drilling the side of the electrical box, clamped to the box and drilled 3 holes, once installed on the electrical box I considered how to mount the arm, and then I thought do I actually need an adjustable arm, maybe not.

So I drilled the center of the piece out using the lathe for the first time and then tapped it with a 10 X 1.5 tap, using the lathe turning the chuck with the jog button, that was easy.

After test fitting it the display sat up quite high so I drilled out about 1`` of the threads out so it could thread in further and the display sat lower, it tightened up in the exact right spot and I left it like that till I pull it apart for painting.

View attachment 318597

View attachment 318604

View attachment 318598

Now onto the install of the scales, this is the part that makes me sweat, drilling into the cross slide and tapping with a 6mm tap, first hole done, I usually drill one hole then align the piece and then mark the other holes with a transfer punch just in case the drill wanders a little, I get to correct for each hole this way.

View attachment 318600

This part finished, now for the scales, I``ll finish those later tonight.

View attachment 318601

I hope the bracket clears the cover as I plan on installing the covers, if not I can always mill out a bit from this bracket to make clearance.

More to come.

David.

Alex

- Joined

- Oct 27, 2016

- Messages

- 286

Great install.

Is that a ‘65 Beetle?

Sent from my iPhone using Tapatalk

David, thanks for the compliments, the Beetle is a 1966, but it's not mine, a friend is storing a few cars in my workshop for a few months, which is now a few years,

David.

Last edited:

- Joined

- Oct 27, 2016

- Messages

- 286

Hi Alex, glad you're having fun with your machines as well, it sure is nice to be able to make stuff when needed or just tinkering in the shop for fun.Good to see you're still at it David. I basically was lazy and bought the same lathe with the DRO installed by Matt's crew but did ultimately install Mark's control system and it is SLICK I agree, that jog is so handy as is the proximity sensor for the carriage. Nice work there, we're doing much the same thing, I've knocked off some parts for my bikes, mostly fasteners that are unique and were trashed and even made a top for a triple tree to fit as set of GSXR forks on my friends cafe Racer build. The tools are great to have and one learns endlessly from them.

Alex

BTW I'm glad I don't install DRO's for a living as I would be very poor based on how long it takes me, haha.

David.

- Joined

- Oct 27, 2016

- Messages

- 286

Well , I got the X scale installed or is it the Z, it turned out really well.

I used 1/2" aluminum for the vertical bracket and a block of 5/8" for the bottom bracket, I ended up putting a piece of angle on the block and attching the read head through the side as the 4mm screws on the bottom are very shallow and it seemed like a really tough way to go so I took the route with the most room for adjustments, took a lot longer but worked out well.

I Installed the cover and then fitted the backsplash and also installed the light and wired it into my 24VDC power supply.

My son and I went through the programming and he setup the jog to run at 30hz set the 2nd stage braking to 3 seconds and also optimized a few others things which I've forgotten already.

A few shots of the finished install.

Shot of the almost finished control panel, just need to install the switch for 2 stage braking and maybe a bypass switch for the proximity stop.

I used 1/2" aluminum for the vertical bracket and a block of 5/8" for the bottom bracket, I ended up putting a piece of angle on the block and attching the read head through the side as the 4mm screws on the bottom are very shallow and it seemed like a really tough way to go so I took the route with the most room for adjustments, took a lot longer but worked out well.

I Installed the cover and then fitted the backsplash and also installed the light and wired it into my 24VDC power supply.

My son and I went through the programming and he setup the jog to run at 30hz set the 2nd stage braking to 3 seconds and also optimized a few others things which I've forgotten already.

A few shots of the finished install.

Shot of the almost finished control panel, just need to install the switch for 2 stage braking and maybe a bypass switch for the proximity stop.

- Joined

- Oct 11, 2016

- Messages

- 3,857

very clean install, @Kiwi Canuck !

I'm in a similar momentous project thing right now. I have 80% of a 15X60 LeBlond completely disassembled lathe on my workshop floor, along with 70% of a BP clone, waiting for COVID19 to end so I can pick up the remainder and reassemble them...

I've been following your thread for quite a while now, silently. I used to own a house in White Rock (and still visit regularly), and my cousin lives in Ladner. Next time I'm there (well after the pandemic) we might have a coffee if you are free.

I'm in a similar momentous project thing right now. I have 80% of a 15X60 LeBlond completely disassembled lathe on my workshop floor, along with 70% of a BP clone, waiting for COVID19 to end so I can pick up the remainder and reassemble them...

I've been following your thread for quite a while now, silently. I used to own a house in White Rock (and still visit regularly), and my cousin lives in Ladner. Next time I'm there (well after the pandemic) we might have a coffee if you are free.

- Joined

- Oct 27, 2016

- Messages

- 286

Thanks for the comments Dabbler, I would be up for that, let me know when you'll be here next time.very clean install, @Kiwi Canuck !

I'm in a similar momentous project thing right now. I have 80% of a 15X60 LeBlond completely disassembled lathe on my workshop floor, along with 70% of a BP clone, waiting for COVID19 to end so I can pick up the remainder and reassemble them...

I've been following your thread for quite a while now, silently. I used to own a house in White Rock (and still visit regularly), and my cousin lives in Ladner. Next time I'm there (well after the pandemic) we might have a coffee if you are free.

David.