- Joined

- Sep 28, 2013

- Messages

- 4,307

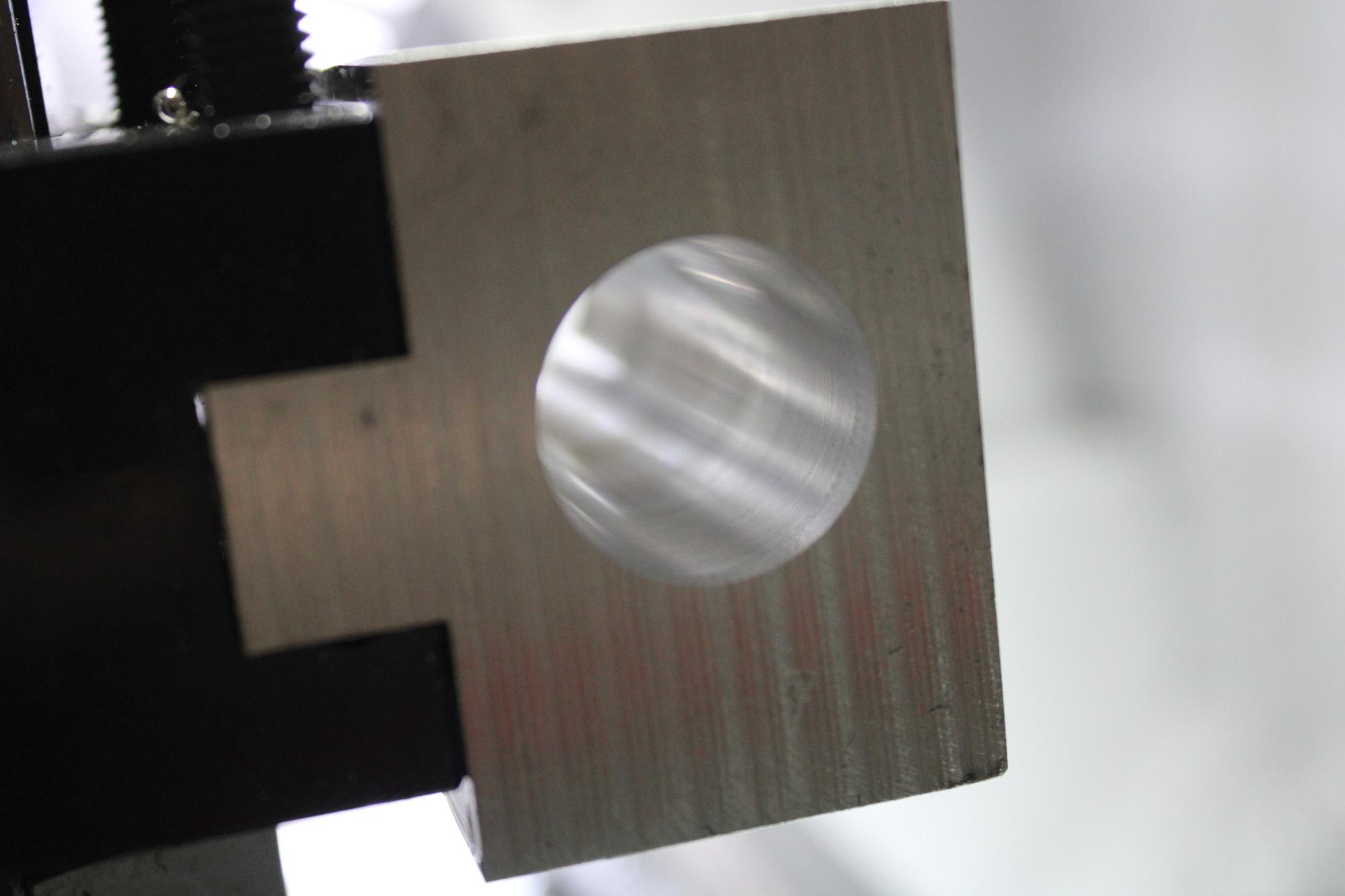

that's a seriously impressive project! I can't tell from the pics, but did you finish grind the bearing seats? Will you be balancing the spindle when you're done?

Thank you! The bearing seats on this one are not ground. The next iteration will be hardened and ground though.that's a seriously impressive project! I can't tell from the pics, but did you finish grind the bearing seats? Will you be balancing the spindle when you're done?

There might be a market for it, but I have a hard time imagining it would be cost effective to make these. It is a ton of work, so it would be very expensive to be worth the time to do it.Looking good man. I think you are really onto something with the BT30 cartridge that fits in the existing head... Could even be a real market for it!

Just curious, what is the diameter of the spindle housing? I'm pretty sure my 940 has a 75mm spindle housing... Maybe you see where I'm going here?

Keep up the good work!

PZ

If you have a 3D printer it can help with mock ups, slow but can work.WoW, just read this impresive thread from start to finish, its comming along very nicely. I'm just starting my conversion, I have the ballscrews with double antibacklash ballnuts, Material for table and enclosure, material for the endfittings to mount the motors. My mill is a pm25mv rebadged as HBM Bf28, it has 1.1kw brushless motor with 2 speed pulley belt drive. Its my only mill so what I intend to do is dismantle 1 axis at a time, measure and draw out parts, rebuild and manually machine them, fit and move onto next axis and repeat, I was thinking of going with 2 shaft steppers so as not to lose manual mode but with a pendent fitted I think I can do the same thing as manual but using each motor to wind the handles.

For th OP shooter123456, the newer pm25mv have been modified, the X and Y endplates now have 70mm centres on the fixing bolts to table so dont rush out too many kits at the old measurment of 120mm between centres as you might get stuck with them for a while. If you would sell a copy of your drawings, especially the fastening nuts that fasten ballnut to table/sled, I would be interested as I'm not looking forward to modeling especially Z axis, disasemble check fit, reasemble and modify a couple of times to get it right, then repeating same on other axis. Let me know.

I've been thinking of using 5.5nm(778 oz/in) nema 24 al round or even next size down for X and Y, the nema 24's fit nema 23 mounting plates that I have so thats not a problem, Ill be watching the rest of the build in the front seat, thanks for sharing.

You might want to check this out on youtube.. his free plans are nice Fusion modelsAs it happens I do have a 3d printer, not used it in a while, if its an .stl file they can now be loaded in fusion 360 AFIK, I do have some fusion files for the G0704 but they are slightly different. Anything rather than disarming everything especially Z as you upset trim aswell.