-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New PM-728V-T Mill

- Thread starter AlanB

- Start date

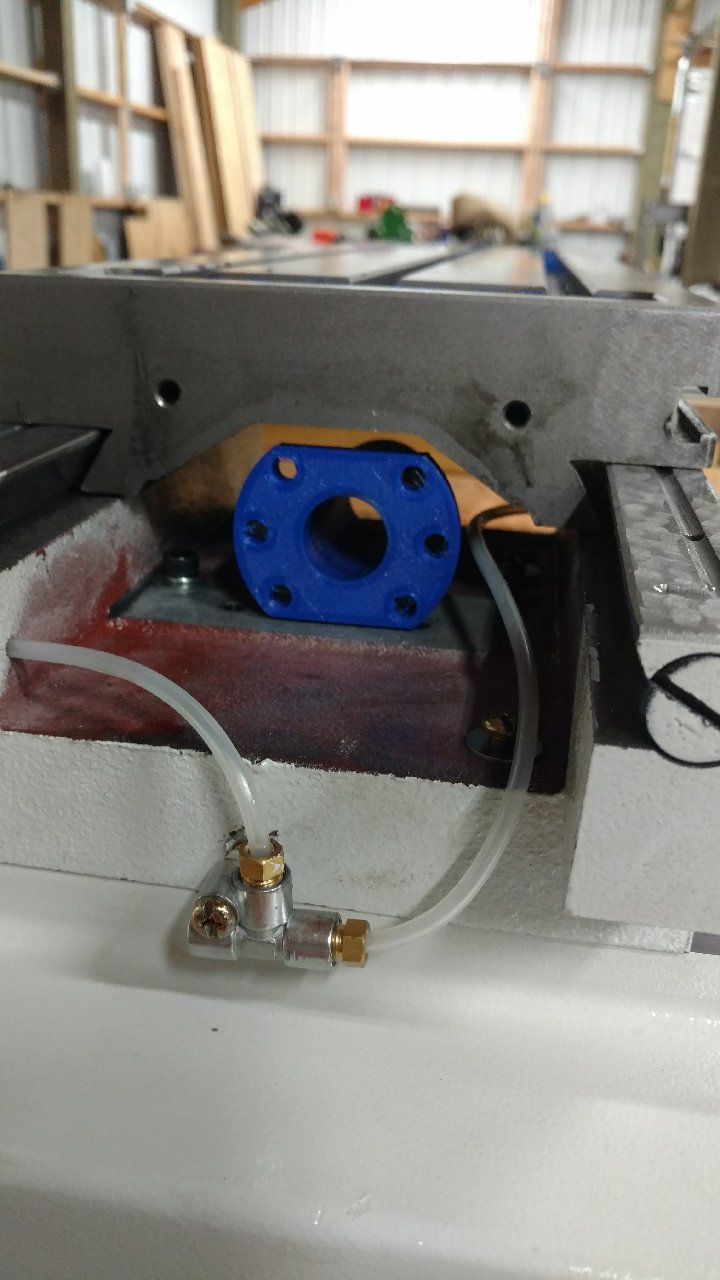

I printed a 2005 ball nut and mount for a mockup. The leadscrews are 20mm so using them to test. The Y has plenty of travel and look at X, plenty of room. The X mount is printing as I type. Waiting is not my strong suit. When PM says their kit will be a drop in I believe it. I don't think it could get any better. The Screws, double nuts, and FK-15 mounts have been ordered from Chai.

Did you check the tram of the spindle to the table before you tore it down? I know you can easily adjust the tilt side to side but the nod I believe would need to be shimmed where the base meets the column. I'm just curious how well it was set-up straight from the factory.

Planning on CNC so went right to teardown. Very impressed so far.

I guess the quill tolerances aren't any concern to anyone who are converting their 728V-T's to CNC as it won't be used. I would assume that''s why my question is of little importance. I only ask this because I have read several other threads about the various models of PM bench mills and the one complaint they all have is the slop between the quill and spindle and the backlash in the gearing for the quill. I guess I am the lone wolf on this forum, most of the threads in this section are about converting these mills to CNC. I am interested in these mills as an alternative to a manual Bridgeport type mill. Hopefully someone will chime in. Thanks

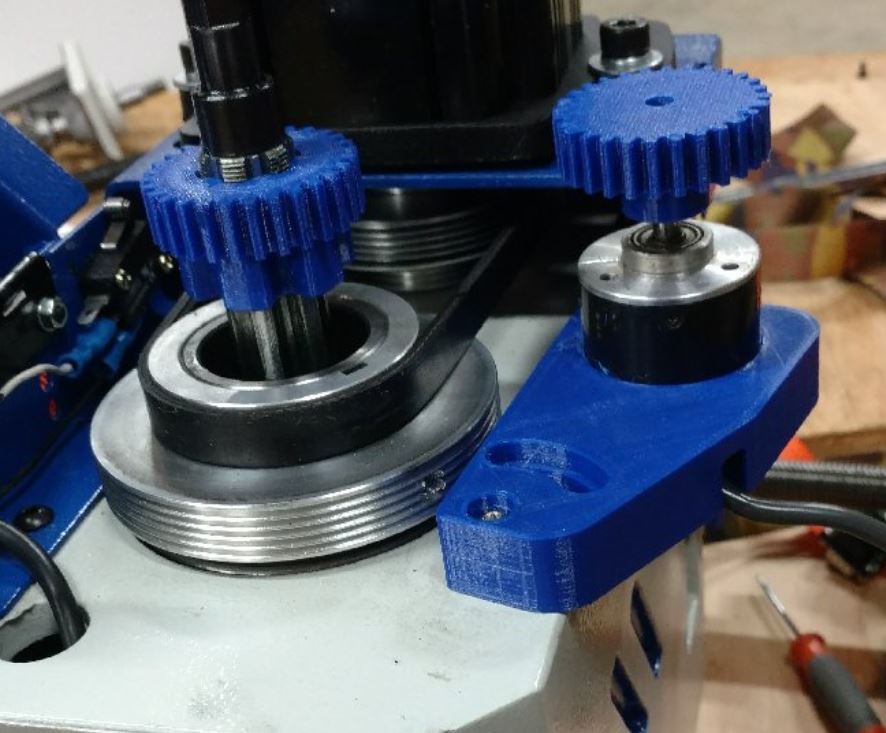

Waiting on hardware so used my printer some more. The Acorn board has a good setup for reading spindle RPM so looking for options to drive the encoder. This should work. Also could place it straight ahead for less overhang. Want to do a PDB and have them play nice together.

- Joined

- May 17, 2020

- Messages

- 5

This in my first post  and my first mill PM728 I haven't taken it out of the crate yet as i'm waiting for CNC kit to become available before getting into it so i'll be watching this thread and forum for content and knowledge.

and my first mill PM728 I haven't taken it out of the crate yet as i'm waiting for CNC kit to become available before getting into it so i'll be watching this thread and forum for content and knowledge.

The photos already posted are very helpful, lets me know what to expect.

The photos already posted are very helpful, lets me know what to expect.

Ditto -- except no crate in hand yet, as my 728 w/DRO is still on the proverbial "slow boat from China." In the meantime, I have used the photos that have been posted to figure out how much space to clear for the 728 and a 1030 lathe, while awaiting the arrival of the shipping fairy's delivery truck. So, thanks for the posts!This in my first postand my first mill PM728 I haven't taken it out of the crate yet as i'm waiting for CNC kit to become available before getting into it so i'll be watching this thread and forum for content and knowledge.

The photos already posted are very helpful, lets me know what to expect.

The waiting is driving me nucking futz!

- Joined

- May 17, 2020

- Messages

- 10

I'm in the same boat as you, ordered it with the DRO so have been waiting patiently as I can.Ditto -- except no crate in hand yet, as my 728 w/DRO is still on the proverbial "slow boat from China." In the meantime, I have used the photos that have been posted to figure out how much space to clear for the 728 and a 1030 lathe, while awaiting the arrival of the shipping fairy's delivery truck. So, thanks for the posts!

The waiting is driving me nucking futz!(but no problem with PM's service -- can't blame them for transport/customs/virus issues beyond their control)

I don't have any plans for CNC though as ill mostly be using it for hobby gunsmithing and probably a motorcycle part/bracket or two when needed. Assuming I get decent using a mill as I have absolutely 0 experience with any mill lol. Also don't know how to program CNC so would be lost there..