Thanks. Yes. Spell correct has mind of its own.

it’s been a good process for me.

Also - In in my rush to post I failed to send out a thankyou to everyone that helped me get here.

Super helpful at every turn - so to speak...

Collet closer - I agree - and in fact - had done some work on it already.

Next person should have it and functional if possible.

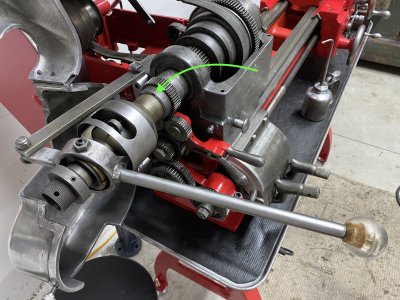

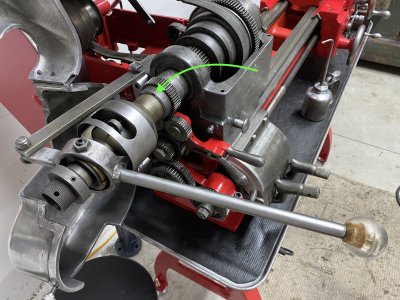

I wrestled the apron to the ground until the clutch operated smoothly and all handles moved well/ smoothly - read - took it back apart after I had it nicely sealed with gasket sealer...

Then - I turned my focus to the collet closer.

Here - I got a fair ways along but had some questions.

Some pics below:

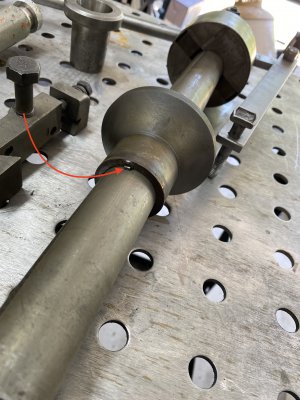

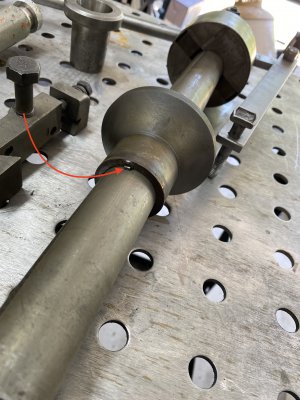

1. Does the part that fits in the spindle look correct? It doesn’t seat all the way into the spindle - though it seems a very good fit. Not sure if it is or isn’t the right taper. Can someone with experience let me know if this is how it should seat - or is this the wrong taper part?

2. Have a look at the part that is half way down the closet in this picture. You can see two fairly fine “dogs”. However - there is no reciprocating female detents when it slips inside the spindle tail. Not sure what to make of that.

Here it is inserted in the spindle tail.

Note that the nut that screws on to the spindle tail seams to have two receiving detents for those dogs.

However - my part fits INSIDE this nut - and my dogs seem to want to interface with the spindle tail iteself - which has no detents.

My suspicion is that the prior owner sourced this - but perhaps it was from a different model year.

That said - the parts seam to be there - like the mounting lug off the back of the headset - for the anchor to pivot off of.

Any thoughts on above by those with experience ?