- Joined

- Dec 30, 2016

- Messages

- 51

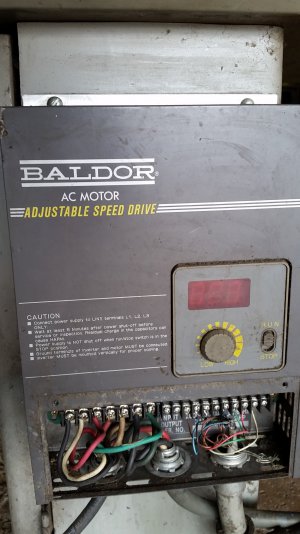

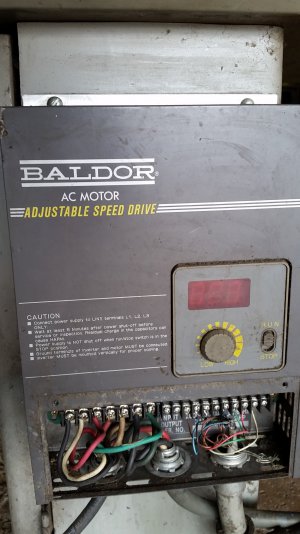

So I picked up a 5904. I've been looking for the 24 inch model for a few years and patience has paid off. It needs a good general look over and new belts. Ways look great for its age. Any body ever swap these 3ph units to 1ph? This unit has a 1.5 hp 3ph motor with a Baldor adjustable speed drive box on it. My only idea for it being there is to soft start the 3ph motor...??? Then again it has a potentiometer wired to the factory variable speed control. Any ideas how this all works?

The lathe came with taper attachment, tail stock, collet closer, a beat up chuck and a quick change tool post I have never seen before but no wrenches/ spindle spanner.

The lathe came with taper attachment, tail stock, collet closer, a beat up chuck and a quick change tool post I have never seen before but no wrenches/ spindle spanner.