- Joined

- Dec 30, 2016

- Messages

- 51

Thanks for all the input. Hopefully someday I can reciprocate. I have a few days of reading and digesting. I have to work on another project first then I can methodically disassemble the lathe for maintenance. I'll be posting this ensemble. For now this needs repair.

Straighten the front end, run through bearings and torque converter, new breaks and cables, and build a cover for the TC.

Then the lathe

Straighten the front end, run through bearings and torque converter, new breaks and cables, and build a cover for the TC.

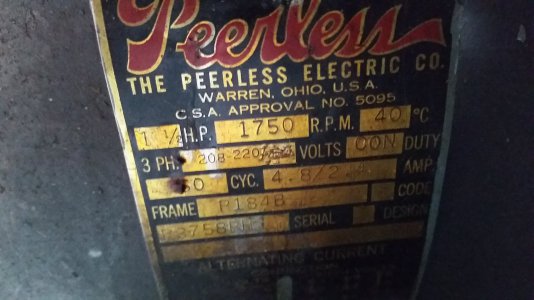

Then the lathe