- Joined

- Sep 1, 2020

- Messages

- 794

I used to deal with some really big rollers in the printing industry 12" diameter x by 8-9ft wide. I have seen that stuff to wonders. I can be a little obsessive and since it is so nice, I do want to put it back to outstanding condition as a user which people after me will want. Since I am shooting for good accuracy and it will run at 5000 rpm, I'd like to get the press fit correct and make it where it can be worked on by someone 80 years down the line. This is going to cost me another $80. In for a dime...

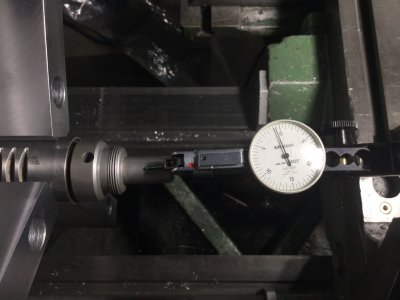

now that I scored a NOS correct chuck and checked run out on my lathe, I'm kinda pumped. For those reasons, I may not be entirely rational about this.

now that I scored a NOS correct chuck and checked run out on my lathe, I'm kinda pumped. For those reasons, I may not be entirely rational about this.