- Joined

- Jan 2, 2019

- Messages

- 6,526

Is it the same as my C frame? Can you measure the ID of the threads?

Robert

Not a C frame at all, more like a welded rectangle.

Is it the same as my C frame? Can you measure the ID of the threads?

Robert

My fear is that even if I buy a new cylinder ($150), I won't trust the C frame threads and I will need to use threaded rod and a plate as a failsafe...so maybe just start with the failsafe?

Next issue:

What am I going to get into if I disconnect the hydraulic line from the cylinder? Do I have to worry about bleeding out air when I reconnect? I have limited experience with hydraulics.

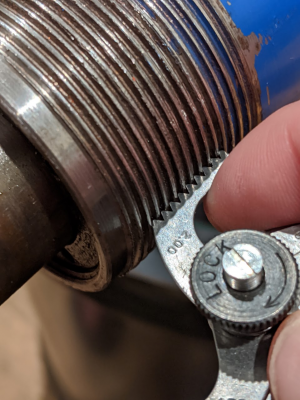

Jim- cylinder is about 2.20" diameter.

View attachment 319976

Robert

What am I going to get into if I disconnect the hydraulic line from the cylinder? Do I have to worry about bleeding out air when I reconnect? I have limited experience with hydraulics.

Jim- cylinder is about 2.20" diameter.

View attachment 320036

Yellow underneath. That paint didn't want to come off but will make a good primer. Even though I stripped it I think I may try to derust it. The table surface is pretty bad.

Robert