-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Old Machine Shop Photos You Might Like

- Thread starter HMF

- Start date

- Joined

- Feb 17, 2013

- Messages

- 214

Almost has a teacher-student look to it.

More to me like: the overseer in the back of the lathe;

"Show me exactly how you screwed this part up exactly?"

Thanks for sharing these fantastic pictures!

Dave

Somebody's gotta say it!

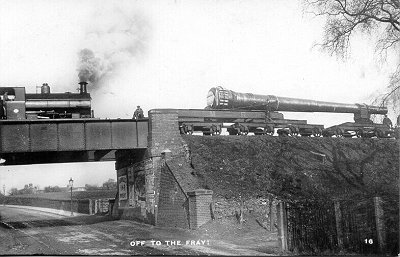

(Aussie accent on) That's not a lathe. This is a lathe.

View attachment 47609

Dang would hate to have a snag, with that load on it.:nono:

I notice no safety glasses, I guess a lot of eyes put out back then also.:whistle:

Jeff

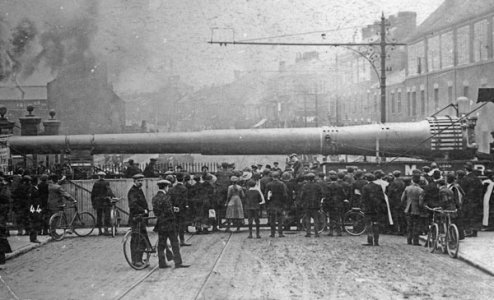

Are they naval guns?I suppose that would be all right for watchmaking. Here in the UK we used proper lathes:

View attachment 47705

)

Richard

- Joined

- Jun 20, 2011

- Messages

- 123

View attachment 47705

You have to love a lathe where you ride the cross slide....

Must be impressive to be on while that giant gun barrel is spinning away peeling off swaths of hot metal...

You have to love a lathe where you ride the cross slide....

Must be impressive to be on while that giant gun barrel is spinning away peeling off swaths of hot metal...

- Joined

- Jan 1, 2013

- Messages

- 185

I would guess the pic of two "engineers" is a publicty photo. Just has that look about it. That means that other than the equipment, there is nothing you can believe.

As for verniers, absolutely, positively, no frigging way I'll use them. Have a six incher that has been untouched for the past ten years. It is very difficult for me to discern all the lines. After I determine which lines line up the best, (I swear there is never a pair that line up exactly) I have trouble discerning which ones they are. All of this makes them an huge source of unneeded error. Batteries and junked twenty dollar dial calipers are emotionally and finacially cheaper than scrapped projects.

Bill

As for verniers, absolutely, positively, no frigging way I'll use them. Have a six incher that has been untouched for the past ten years. It is very difficult for me to discern all the lines. After I determine which lines line up the best, (I swear there is never a pair that line up exactly) I have trouble discerning which ones they are. All of this makes them an huge source of unneeded error. Batteries and junked twenty dollar dial calipers are emotionally and finacially cheaper than scrapped projects.

Bill

Last edited:

- Joined

- Jul 26, 2011

- Messages

- 4,142

I am building a wood carving duplicator. Bought a 40" dial caliper from Shars(I think,or CDCO). They are Chinese,of course. I had some 13" and 14" micrometer standards at work. The calipers were only out .001-.002" even at that distance. I thought that was pretty good for calipers that large. I want to use them only for getting the headstock and tailstock centers,and the spindle and stylus all the same distances apart. Just comparative measurements. Just so they are all the same is what matters in this application. The calipers weren't all that expensive.

- Joined

- Oct 29, 2012

- Messages

- 63

I loved teaching new guys how to use verniers. They would have no problem at all reading mics, but for some reason, once you flatten h barrel out, it would blow their minds. We really had no choice once the pieces got around 30 inches or larger in size. Dial and digital calipers come an go, we had verniers on the shop floor that were purchased in the 1940's.