- Joined

- Jan 25, 2022

- Messages

- 110

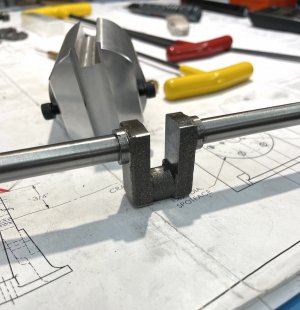

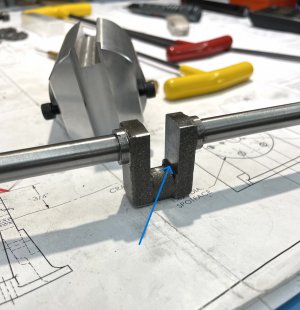

Was making good progress on the crankshaft, running true, good fit in the base, etc., until I cut out the filler.

There must have been some built-in stresses, as the two shafts are no longer in line. Put between centers there is now about 0.012" runout at each web.

The two webs apparently tilted inward slightly when the filler was removed.

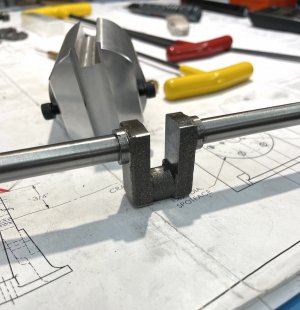

I'll finish it and see if it becomes a problem at final assembly. I can't think of a reasonable fix. Can cast iron be bent ?

Anyone else experience this?

There must have been some built-in stresses, as the two shafts are no longer in line. Put between centers there is now about 0.012" runout at each web.

The two webs apparently tilted inward slightly when the filler was removed.

I'll finish it and see if it becomes a problem at final assembly. I can't think of a reasonable fix. Can cast iron be bent ?

Anyone else experience this?