I have a new 1127 lathe that I'm trying to set up 32 pitch threading on. The threading table provided in the manual and on the lathe list an "H" gear. What is that? Maybe I'm missing something and that "H" isn't a gear at all.

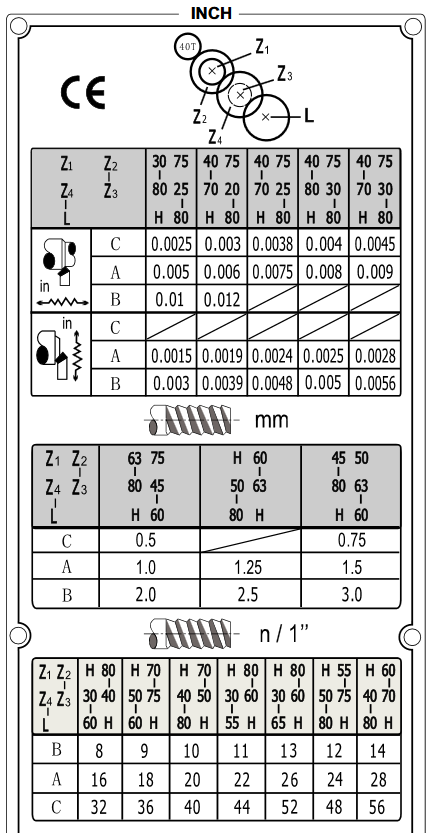

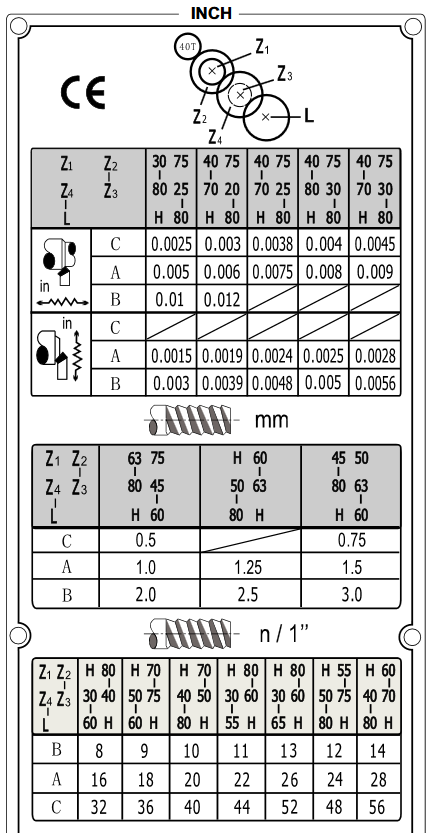

This table is what I'm looking at (32 tpi on the bottom left):

This table is what I'm looking at (32 tpi on the bottom left):