- Joined

- Dec 9, 2016

- Messages

- 1,133

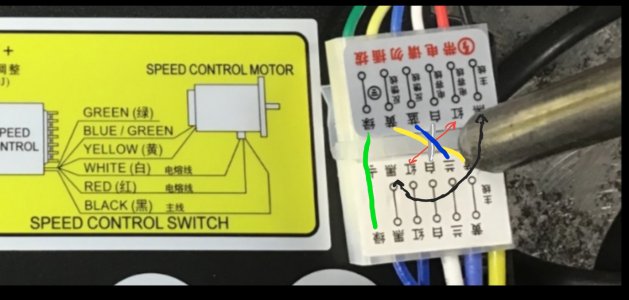

It worked as it came as shown in the pictures or did you need to swap the wires?

I started it, I should explain.Where we going, where we going? Are we there yet? Huh? How much longer?

Be safe.

It worked right out of the box.It worked as it came as shown in the pictures or did you need to swap the wires?

Is it possible the reason it may not be running at the higher speed is due to the wiring not being Exactly correct? I was really looking at those symbols and my interpretation is there seems to be 3 different dialects represented on the tag coming from the controler the 1st in red, 2nd the center section of the smaller grouped symbols, 3rd the larger Black symbols which seem to be the same as the motor symbols which is what i believe would operate the motor at the higher speed you where wanting.It worked right out of the box.

Unfortunately the rpm is too slow.

The advertised full speed was 450. It probably turns at 200.

I think it will work. I’m not thrilled. It was cheap.

Interesting, I’ll take a closer look.Is it possible the reason it may not be running at the higher speed is due to the wiring not being Exactly correct? I was really looking at those symbols and my interpretation is there seems to be 3 different dialects represented on the tag coming from the controler the 1st in red, 2nd the center section of the smaller grouped symbols, 3rd the larger Black symbols which seem to be the same as the motor symbols which is what i believe would operate the motor at the higher speed you where wanting.