- Joined

- Apr 23, 2018

- Messages

- 6,610

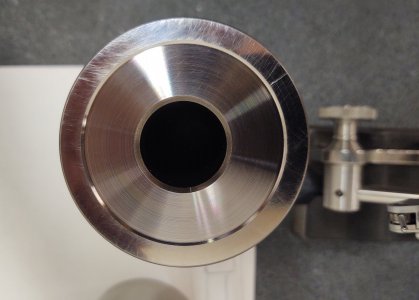

It's Ospho Rust. (yeah, I know Ospho vs. Oxpho is confusing, take it up with Brownell's). The Ospho rust is a lot better than plain naval jelly since it has chromic acid in it, but it's also kinda nasty stuff that should never be used unattended, and pity the foo who leaves something in it overnight. It blackens very well with heat. Pre-warming a part with a heat gun then dunking it is Ospho is rock and roll, and leaves a solid grey-black finish that takes Cerakote and selenium bluing very well.

Pity this foo who left his files in the solution on Friday evening to be found on Saturday morning. That foo was me. The files came out clean and etched sharp, but that is a lot of leaching of manganese from the metal matrix. Not recommended. This was intended to be a 60-minute treatment, but I am aging along with the rest of you. Consider it a goof to avoid.

Pity this foo who left his files in the solution on Friday evening to be found on Saturday morning. That foo was me. The files came out clean and etched sharp, but that is a lot of leaching of manganese from the metal matrix. Not recommended. This was intended to be a 60-minute treatment, but I am aging along with the rest of you. Consider it a goof to avoid.