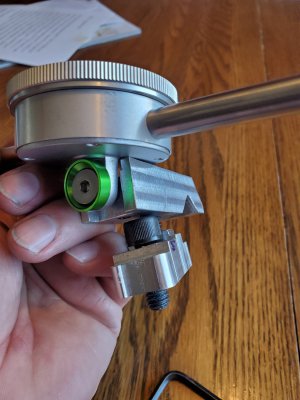

As I've been working on the Hemingway rotary broach kit, I found that my micrometer doesn't allow me to get close enough to the broach in a 5c collet. I needed another way to get closer to the headstock, while allowing me to at least measure closely. I've seen people make their own dial indicator holders before, and thought it was time for me to have one. I made two, one that is the normal v-ways clamping style, and the other that uses two 1/4"-20 holes right above the quick change gear box. I think transfer screws are one of the coolest inventions!

View attachment 459442

View attachment 459443

View attachment 459444

View attachment 459445

With a 2" indicator (I have a 1" I can use if I need to), I should be able to get really close to the headstock for parts in a collet. Now I can move on to making the broach itself.

I did have to use the lathe to undercut the screw heads so that they'd hold the indicators flush, and the v-ways variant has two orientations for the indicator to be bolted up in - facing upwards and facing outwards. All parts were machined from scrap pieces (cut-offs and drops) that were donated by my neighbor.