I might just have to build an annealing machine, there is no substitute for mechanizing the process. As with everything in reloading, volume changes everything.

@Eyerelief, did you build that 'un? Do you have plans or prints? I've seen a few different schemes, and the one with the window rollers is my favorite. What type of motor did you use?

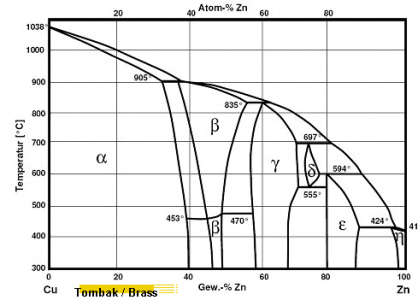

Brass has no triple point, so it's technically not annealing, but stress relieving and normalizing the grain structure following work hardening. It's not really changing the molecular structure as much as it is repairing it, cartridge brass is always in the alpha structure (centered cubic) so calling it an anneal is just shooter slang. I went into the shoulders on purpose, since these have been worked through 3 dies so far with one more to go, and the first bang will fire form the last tiny remainder of the shoulder and neck junction.

View attachment 462465

Cartridge brass is 30% copper by weight, or one copper for eight zinc atoms. What changes isn't the structure, as steel does, but the grain.

View attachment 462466

This shows what's happening with the grain. At 750 F, the work hardened grain is reformed as a ductile grain. This graph does not include time, so I am assuming it is a one hour time constant. I'm doing this for longer case life and an easier time on the bench.

Yes, I looked this stuff up before I got started. I don't believe in voodoo or reading the bones. Shooters are the most superstitious folks out there. The web is full of what and short on why when it comes to this kind of stuff. LIke waving a rabbit's foot over a keg of powder with a different lot number than the last one seems to help a lot of guys shoot better groups.