- Joined

- Nov 28, 2016

- Messages

- 2,344

It's a little coincidental that the conversation has turned to circular saws...

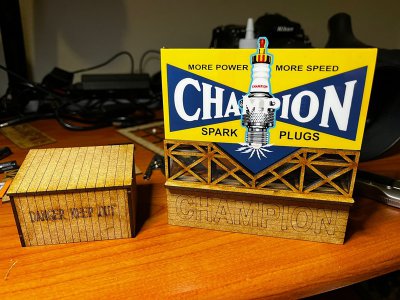

Right after I finished up with the angle grinder, I started tinkering with a Skil 77 that I picked up a few weeks ago...

View attachment 466939

It runs pretty smooth... or it does with no load... I'll get back to that.

The power cord had been cut and spliced a few times, and it was terribly nasty, but seemed to be in good condition for $10...

I started to disassemble it yesterday to clean it good... the deeper I got into it, the worse it became. To start with, the rear handle had a hairline crack above the trigger and fell apart upon disassembly.

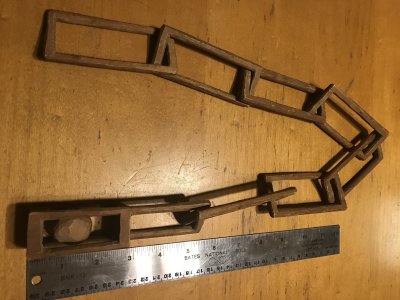

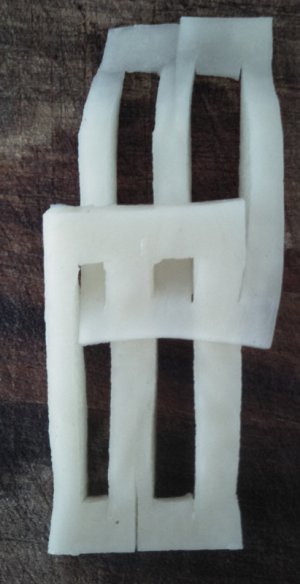

The brushes looked very good, but after removing the motor housing, it's apparent that the commutator needs some attention... that's not a big issue. As I was removing the armature from the gearbox housing, I found this...

View attachment 466942

It might have spun smoothly with no load, but under load may have been different...

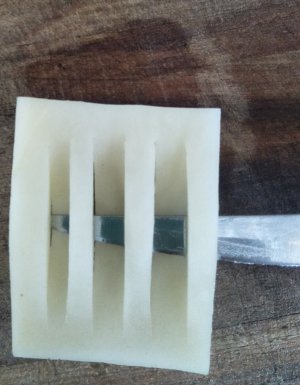

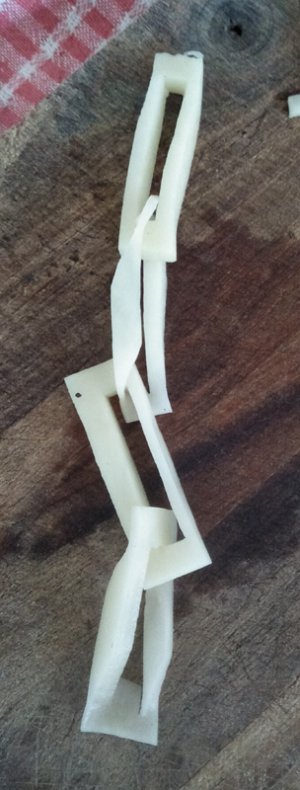

After removing the armature, I discovered the bearing on the other end is almost locked... and the front of the motor housing in front of the fan was completely packed with a mixture of sawdust and gearbox oil...

View attachment 466943

There is supposed to be cooling slots through there...

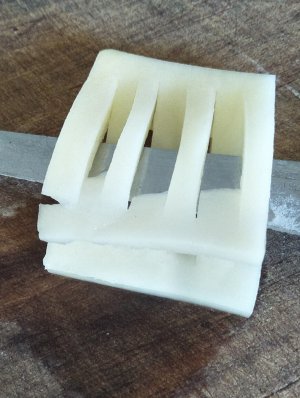

On a brighter note, the worm gear set looks very good, with just a very small amount of wear...

View attachment 466944

But then... after cleaning the crud off the gearbox housing, I discovered a crack in the casting... I don't know how serious it is, I have it soaking in the cleaning tank. I'll have to clean it good and evaluate it.

So... I'll need a power cord, two bearings, a new handle, new gearbox housing, and the operating handle on the lower guard is missing. All of these parts are available... but the cost is prohibitive, considering that I can still buy this saw new for around $150...

It may wind up parted out on ebay... IDK.

-Bear

An update on the saw...

The crack in the gearbox housing is on one corner... this corner is about to break completely off...

I had about decided to scrap the saw... then found a good used gearbox housing on ebay for $20... I went ahead and bought it, even though I'm about to have more invested in this saw than it's worth.

I have been known to throw good money after bad occasionally...

Anyhow... I started reassembling the saw this afternoon...

I think maybe I have everything I need to finish it... maybe...

-Bear